4 min read

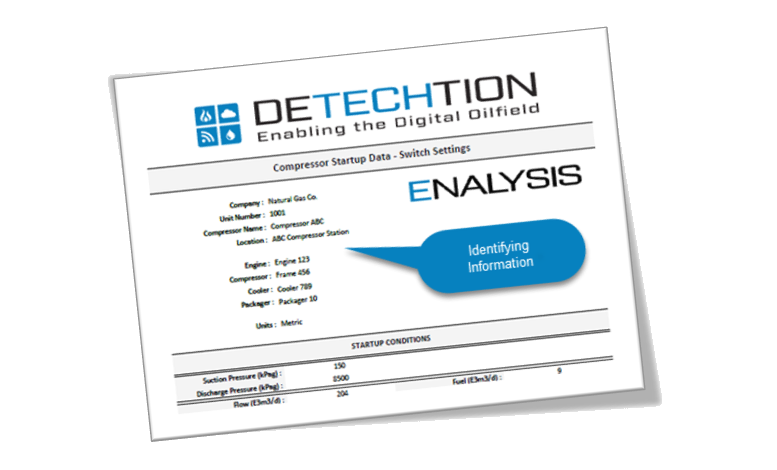

Enalysis Tip 1.14 - Compressor Performance Modelling with Enalysis Simulate

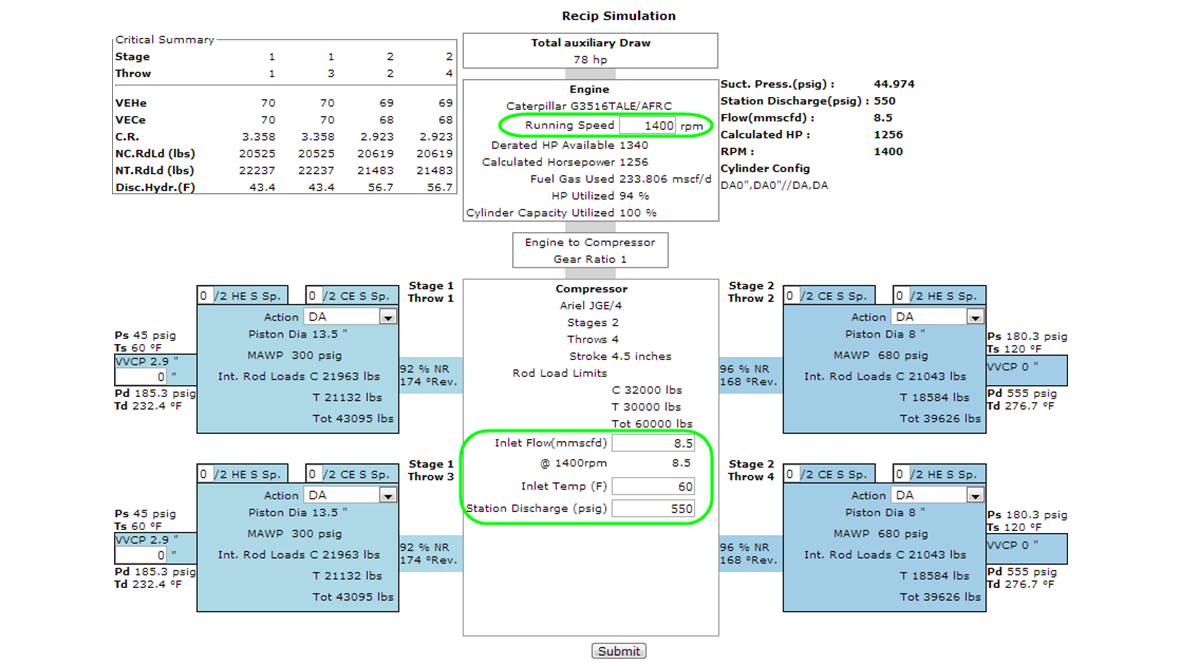

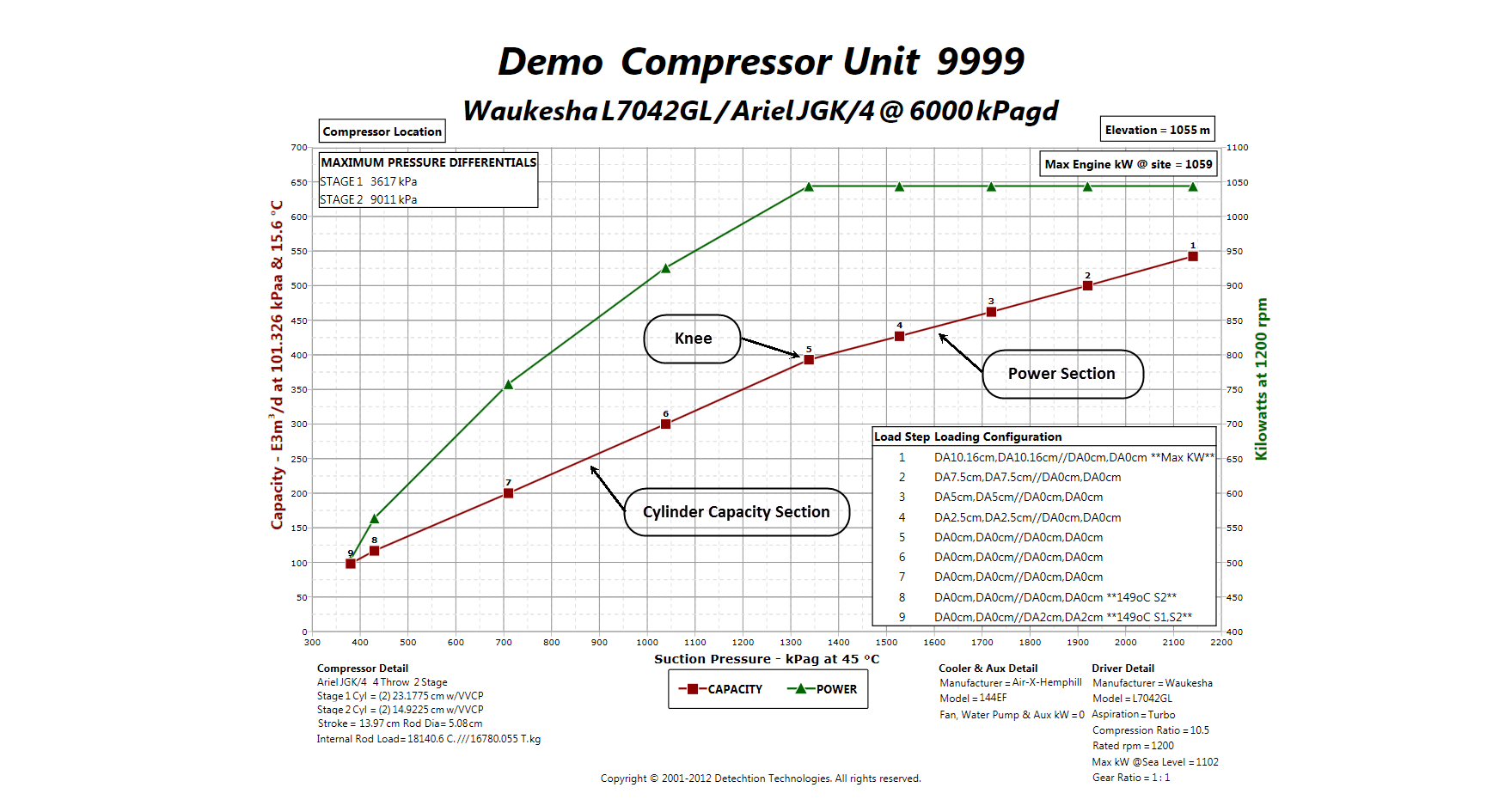

Enalysis includes a full-featured compressor simulator for all active units enrolled in the software. The simulator uses the same calculations and compressor set-up information already in place within Enalysis to simulate the compressor’s...

Read More