Houston, TX |

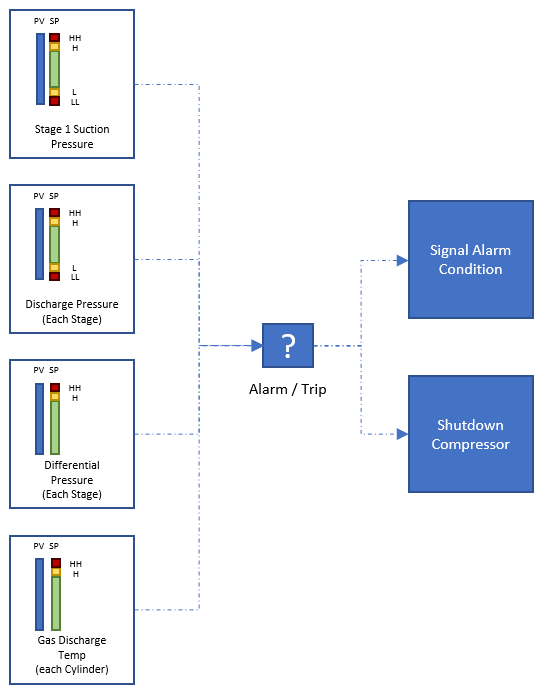

This Enalysis Tip details Detechtion Technologies’ recommended procedure for determining the shutdown, alarm and control settings for a reciprocating compressor. Compressor safety shutdown systems consist of pressure, temperature and vibration sensors combined with a set of annunciators and switches. Alarm and shutdown triggers are applied to critical sensors to prevent operating under any conditions that would exceed compressor rated limits. Alarms provide a warning to an operator that a limit is being approached, while triggering a shutdown will immediately cease the operation of the compressor. Therefore, it is essential that each shutdown is set such that the compressor is always protected, while still allowing a sufficient operating range so as not to limit gas production.

Safety Shutdown System (Recap)

The protection of any compressor meeting the minimum requirement for safety shutdowns depends on the static shutdown trip settings on the following monitored process parameters:

- Low (Stage 1) suction-gas pressure

- High discharge-gas pressure (each stage)

- High discharge-gas temperature (each cylinder)

The operating range can be increased by adding alarm and shutdown settings on the following monitored process parameters:

- High (Stage 1) suction-gas pressure

- Low discharge-gas pressure (each stage)

- Differential Pressure (each stage)

SAFETY SHUTDOWN AND ALARM SYSTEM

Procedure for Compressor Shutdown and Alarm Settings

- Determine the final stage high discharge-gas pressure shutdown (PSHH)

- Must exceed highest expected discharge line pressure

- Must be less than final stage MAWP

- Determine appropriate modelling conditions

- Highest expected Stage 1 suction temperature

- Highest expected interstage suction temperatures

- Anticipated interstage pressure drops

- Determine desired compressor configuration

- Compressor running speed (RPM)

- Cylinder action (Double-Acting, SAHE, SACE, NA)

- Pocket positions (VVCP, FVP)

- Other Added Clearance (spacers)

- Determine high discharge-gas temperature shutdown for each stage

- Determine high pressure shutdowns for each stage

- At final stage PSHH, model increasing suction pressure until limit reached on any stage

- Determine Stage 1 low discharge-gas pressure (PSLL) shutdown at PSHH

- At final stage PSHH, model decrease suction pressure until limit reached on any stage

- Determine interstage low discharge-gas pressures

- Interstage pressures at lowest expected operating discharge pressure and Stage 1 PSLL

- Determine maximum allowable differential pressure for each stage

- Minimum differential pressure for each stage at which rod load limits are reached

- Determined by vendor or 3rd-party software

- Determine alarm settings for each shutdown

- Set at appropriate margin shutdown considering:

- Suction and Recycle valve Controller response time – digital controllers are generally faster acting than local pneumatic controller

- System dynamics – how quickly can process conditions change if the controller fails to rectify the process upset

- Operator response time – allow enough margin for an operator to respond and intervene

- Set at appropriate margin shutdown considering:

- Determine high Stage 1 suction pressure control

- Set high suction pressure for the suction control valve

- Maximise driver power without over loading

- Determine low Stage 1 suction pressure recycle control

- Set appropriate to avoid low suction trip

- Consider upstream processes (ie. water-handling)

- Determine final stage discharge control

- Set appropriate to avoid PSHH

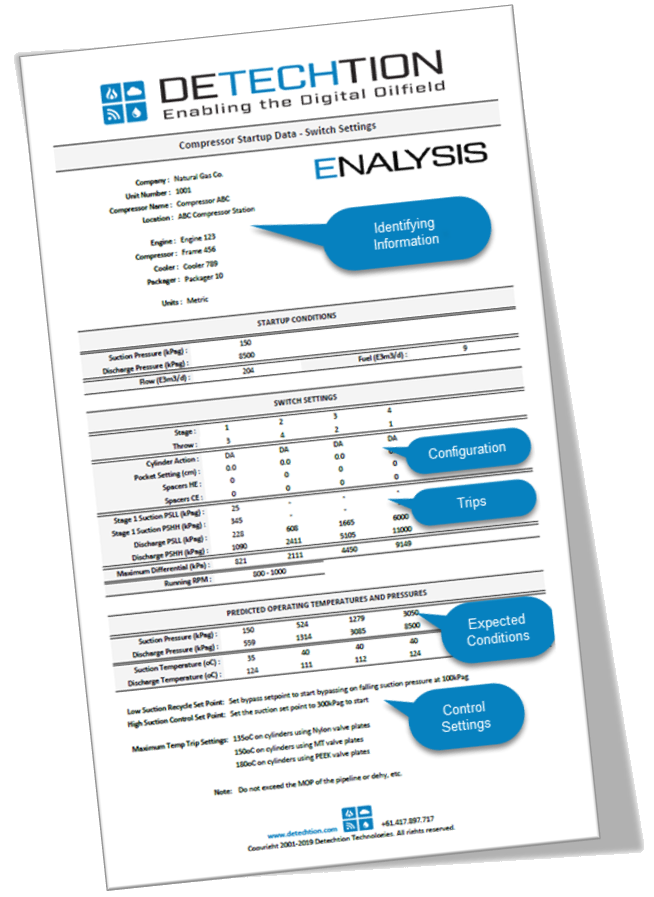

Detechtion Startup Package

As part of Detechtion’s standard services, your Engineering Account Manager will be happy to develop a Startup Package to ensure that your compressor is properly protected. A new Startup Package should be developed every time the compressor configuration is modified or the final stage PSHH is changed.

A Detechtion Startup Package includes:

- Compressor Identification

- Company

- Location

- Compressor Name

- Equipment Make and Model

- Startup Conditions

- Capacity

- Compressor RRPM

- Suction and Discharge Pressures

- Compressor Configuration

- Cylinder Action

- Added Clearance

- Pressure Trip Settings

- Maximum Allowable Differential Pressures

- Allowable Operating Speed

- Predicted Operating Temperatures and Pressures

- Low Suction Recycle Set Point

- High Suction Control Set Point

- Maximum Temperature Trip Recommendations

Limitations of Standard Shutdown and Control Settings

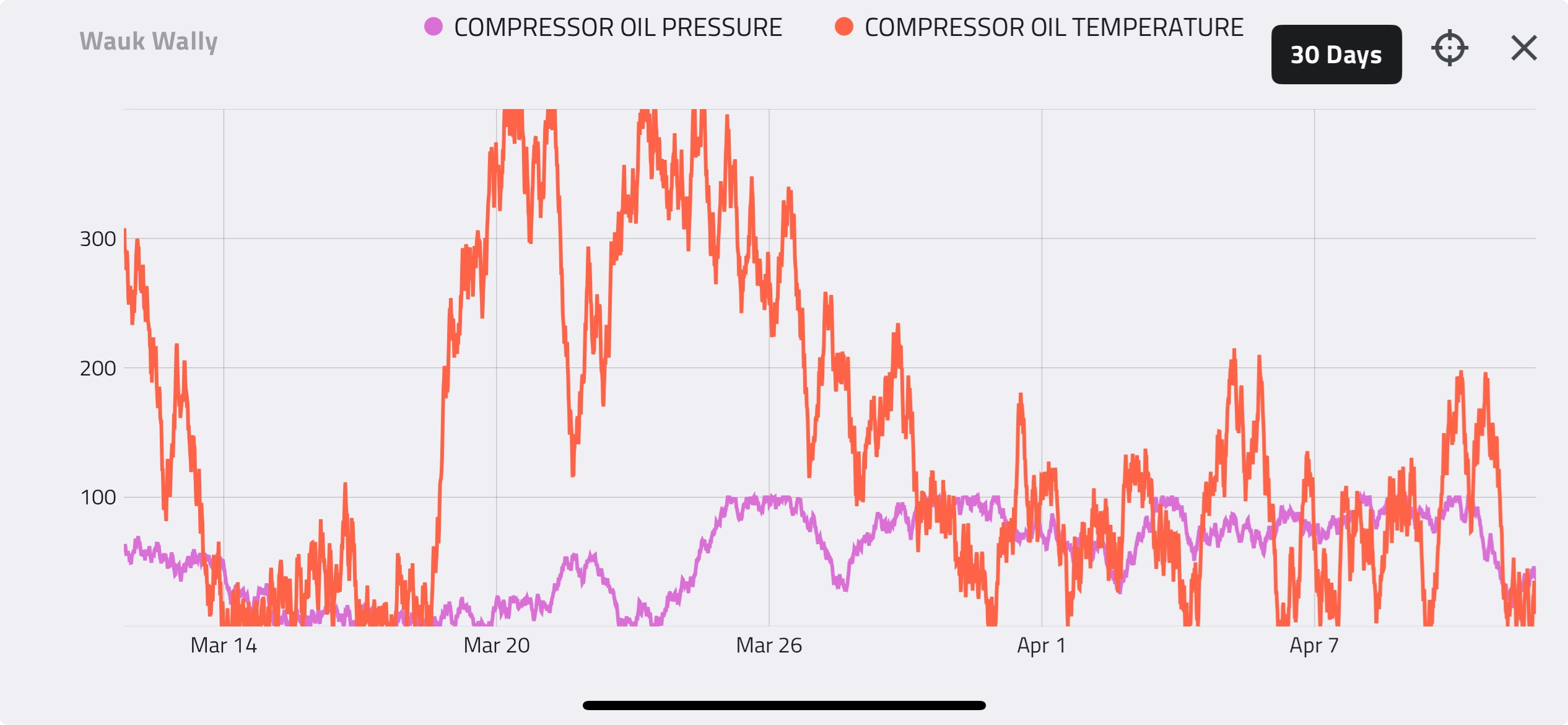

Standard compressor safety shutdown systems use static pressure and temperature trip points. This requires that a “worst-case” scenario of operating conditions be consider when determining safety shutdowns. The most important consideration in determining all shutdown and alarm settings is the required final stage high discharge-gas pressure shutdown, PSHH. This value must be high enough to accommodate anticipated increases in discharge pressure. However, a PSHH that is unnecessarily high will negatively impact the operating range by limiting other shutdown settings. A high PSHH will result in an elevated PSLL, as discharge temperature, volumetric efficiency and rod load limits will be reached sooner due to the increased compression ratio. This will necessitate a higher recycle valve control point, minimizing the ability of the compressor to pull down suction pressure and stimulate declining fields. A high PSHH will also reduce maximum throughput by lowering the high suction control point to prevent high driver power requirements.

All control, alarm and shutdown points calculated based on a static PSHH will be conservative whenever the operating discharge pressure is less than the PSHH.

Assumed Stage 1 and interstage temperatures also limit the upper and lower range of operation. Elevated temperatures will result in high discharge temperatures being calculated earlier on declining suction pressure and low temperatures will calculate high engine loads at lower suction pressures when high throughput is desired.

Click here to read Enalysis Tip 1.13 - Reciprocating Compressor Performance Optimization now!