Failure Prevention

Peace of Mind with Detechtion

Detechtion prevents failures across compression fleets by optimizing each asset's configuration, proactively mitigating risk, and equipping users to monitor calculated and manufacturer-set limits. Operators can instantly identify when an asset’s performance is compromised, ensuring reliability in oil and gas operations.

What You Don’t Know Will Hurt Your Fleet

Did you know that 11% of compression assets operate beyond manufacturer-set limits or optimal efficiency? This compromises production goals and increases operational risks. Proactively identifying and addressing these issues improves uptime, reduces costs, and ensures alignment with oil and gas production demands.

Insights Sent Right to Your Device

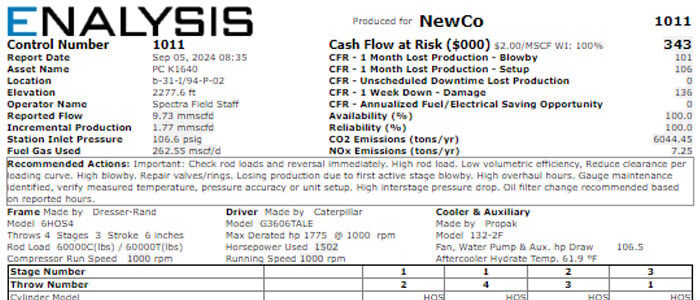

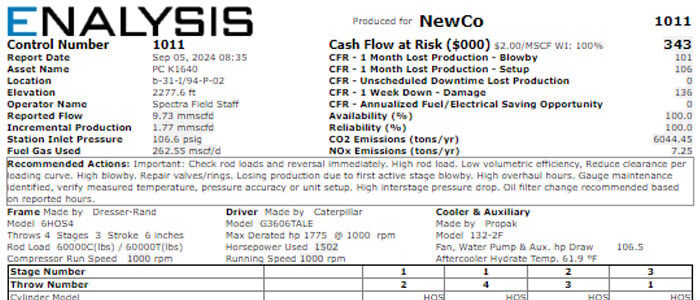

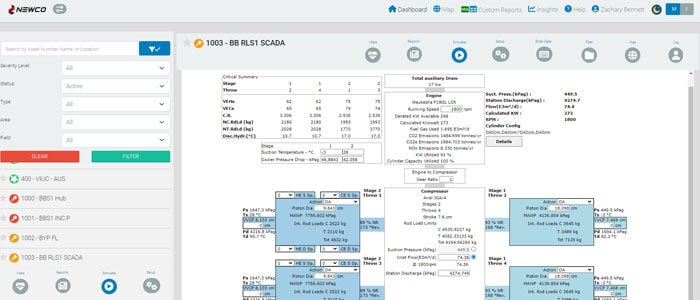

When issues are detected, you’ll have instant insights into corrective actions at your fingertips. While some problems may require repairs or replacements, many can be resolved by adjusting the asset's operating parameters, resulting in low-cost and effective solutions.

Plan for Reliability

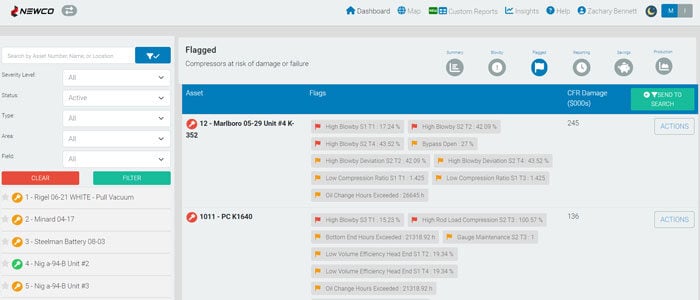

Our solution quantifies the risk of potential failures based on compressor throughput to help you prioritize and plan preventative maintenance effectively across your fleet. The result? More accurate resource allocation, reduced downtime and elevated asset reliability.

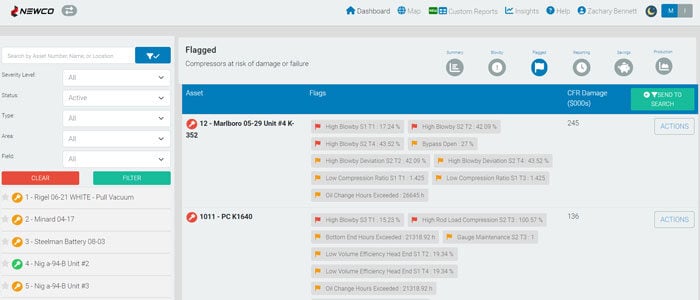

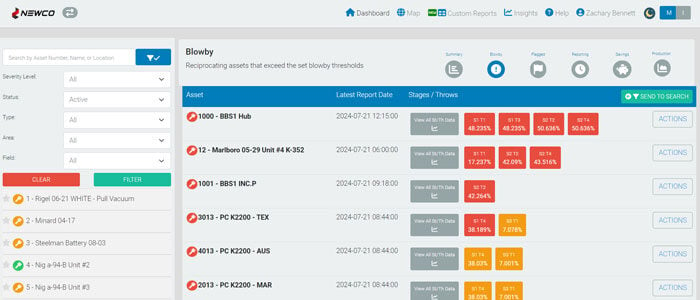

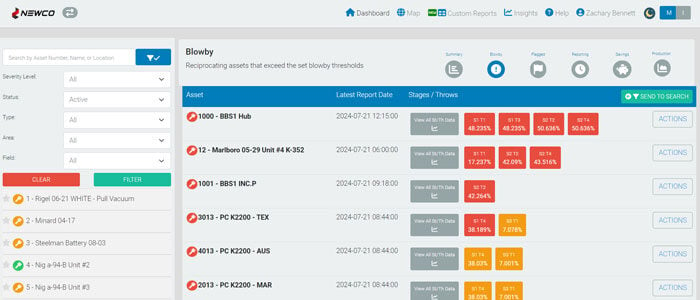

Never Miss a Red Flag

We track 30+ key performance indicators for reciprocating and screw compressors to ensure real-time issue resolution and overall reliability. Our rigorous approach to data monitoring and processing empowers early detection and resolution of issues.

Streamlining Fleet Optimization

Optimizing Maintenance Schedules

Always Stay a Step Ahead

Insights Sent Right to Your Device

When issues are detected, you’ll have instant insights into corrective actions at your fingertips. While some problems may require repairs or replacements, many can be resolved by adjusting the asset's operating parameters, resulting in low-cost and effective solutions.

Plan for Reliability

Our solution quantifies the risk of potential failures based on compressor throughput to help you prioritize and plan preventative maintenance effectively across your fleet. The result? More accurate resource allocation, reduced downtime and elevated asset reliability.

Never Miss a Red Flag

We track 30+ key performance indicators for reciprocating and screw compressors to ensure real-time issue resolution and overall reliability. Our rigorous approach to data monitoring and processing empowers early detection and resolution of issues.

Streamlining Fleet Optimization

Optimizing Maintenance Schedules

Always Stay a Step Ahead

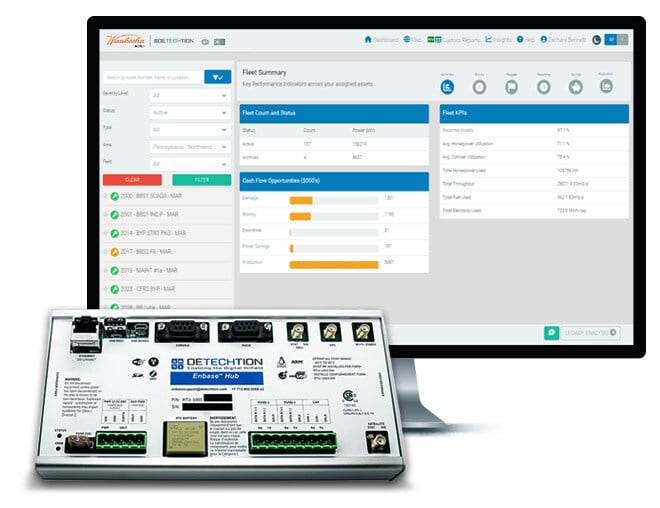

Next-Generation Automation and Asset Visibility Powered By Enbase

Detechtion sets a new standard for compression telemetry, control, and operational efficiency in the oil and gas industry.

Enbase

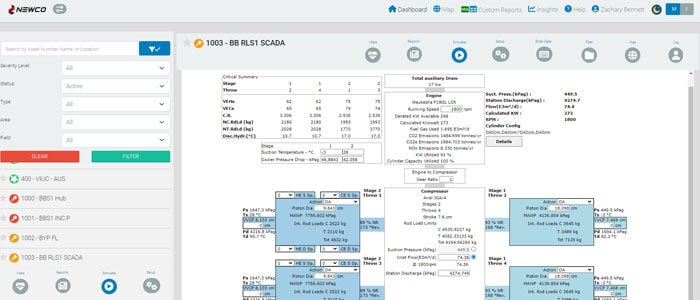

The Enbase Hub integrates seamlessly with existing controllers, annunciators, and pyrometers to provide high-frequency monitoring. It delivers critical data to Enalysis for actionable insights and enhanced performance monitoring.

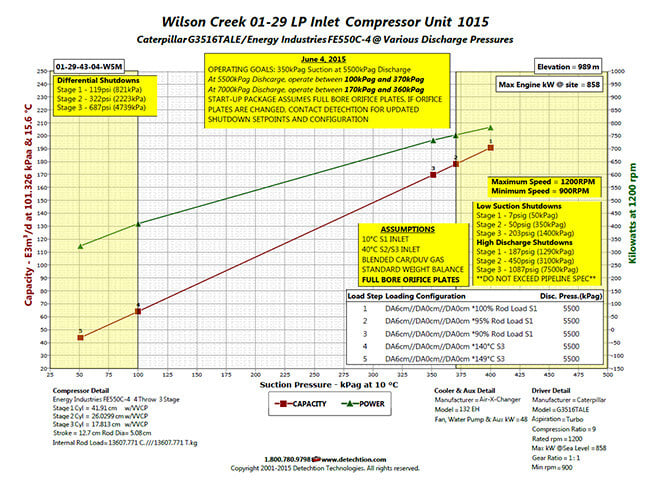

Enalysis

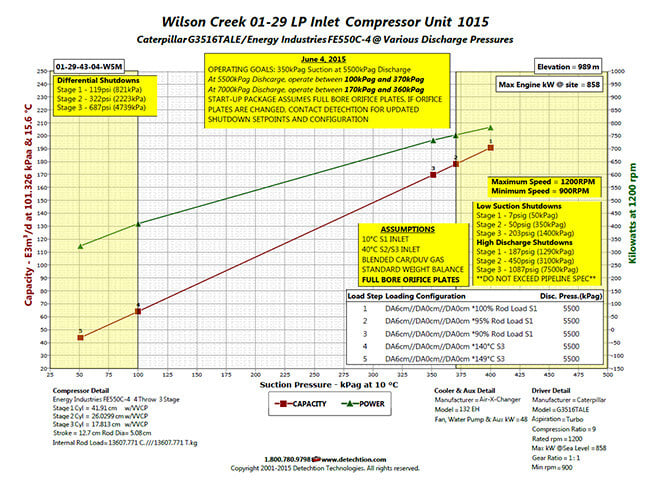

Enalysis combines real-time asset operating data with its digital twin technology to optimize compressor performance, prevent failures, and manage emissions. This cloud-based platform enables companies to maximize efficiency and reliability across their natural gas compression fleets.

Explore our other Compression Management Solutions

Plan Better, React Smarter

Detechtion’s data-driven predictive technology and failure prevention is an investment in your organization’s future. Ready to elevate your fleet with proactivity?

Plan Better, React Smarter

Detechtion’s data-driven predictive technology and failure prevention is an investment in your organization’s future. Ready to elevate your fleet with proactivity?

Achieving $100K in Maintenance Savings by Preventing Compressor Failures with Enalysis

Learn how Detechtion helped one client protect and optimize a screw compressor fleet while maximizing reliability

Compression 101

An introductory guide to the basics of natural gas, compression, types of compressors and the capacity and power behind natural gas compressors.