3 min read

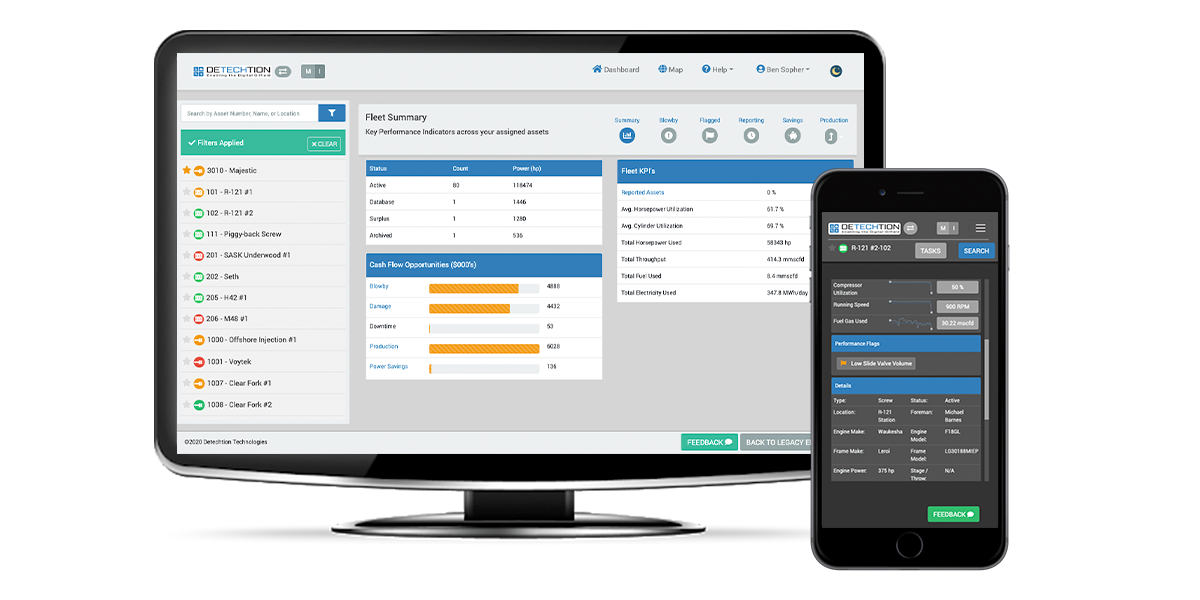

Mobile EAM for Production Operations

Real Problem Solving in Real Time: How Digital Work Order Management Streamlines Operations Work orders have always been an integral component of necessary preventative management and maintenance programs deployed by all sectors of the oil and gas...

Read More