5 min read

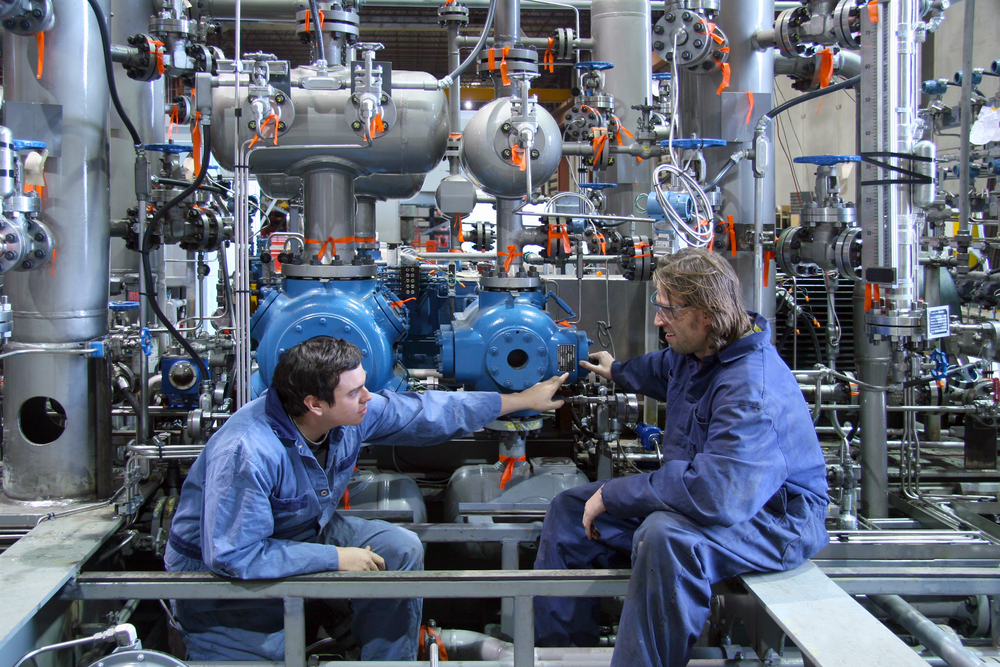

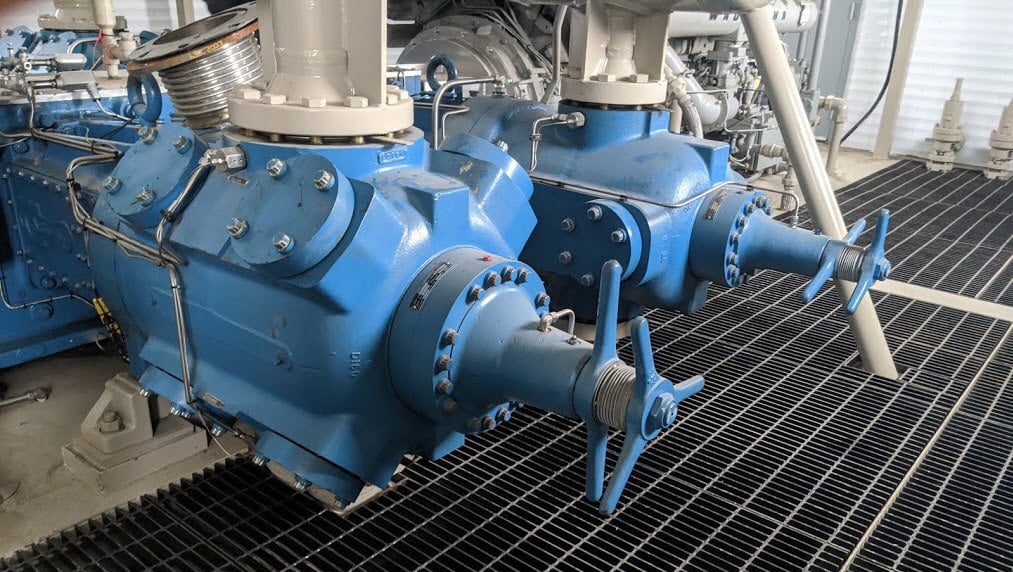

Enalysis Tip 1.11 - Reciprocating Compressor Safety Shutdown Systems

Changes in operating conditions, such as discharge pressure, flow rate, inlet suction temperature or ambient air temperature, will result in a variations of compressor performance. When the changes are substantial, the mechanical limits of one set...

Read More