Houston, TX |

Blowby can result without any physical damage to wear components or unaccounted pressure drops. Improper valve springing can lead to valve flutter, allowing gas to recirculate each compression cycle. Alternatively, high rates of lubrication can lead to oil coating the valve plate and seat, which leads to an increase in pressure differential required to break the stiction when the two surfaces separate. Both are examples of inefficiencies in the compression process and can cause Blowby to flag on an Enalysis report.

Improper Valve Springing

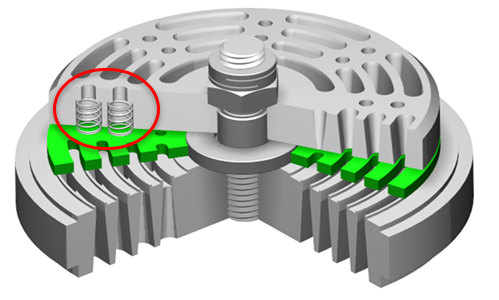

Valves require a pressure differential resulting in a force on the valve plate against the valve springs to open a passage for gas to flow into or out of the cylinder. Without a difference in pressure, the spring force pushes the plate against the valve seat and no gas can flow. If the spring force is too great, then the pressure differential to open the valve can be significant compared to the total compression ratio of the stage. Low compression ratios may be inadequate to fully open the valves if the valves are not sprung correctly. This can lead to valve flutter. Although not damaged, fluttering valves behave like damage and allow gas to slip by the valves when they are supposed to be sealing. This consumes excess engine power and decreases compressor capacity. As well, excess heat is generated, which leads to Blowby on an Enalysis report.

Valves require a pressure differential resulting in a force on the valve plate against the valve springs to open a passage for gas to flow into or out of the cylinder. Without a difference in pressure, the spring force pushes the plate against the valve seat and no gas can flow. If the spring force is too great, then the pressure differential to open the valve can be significant compared to the total compression ratio of the stage. Low compression ratios may be inadequate to fully open the valves if the valves are not sprung correctly. This can lead to valve flutter. Although not damaged, fluttering valves behave like damage and allow gas to slip by the valves when they are supposed to be sealing. This consumes excess engine power and decreases compressor capacity. As well, excess heat is generated, which leads to Blowby on an Enalysis report.

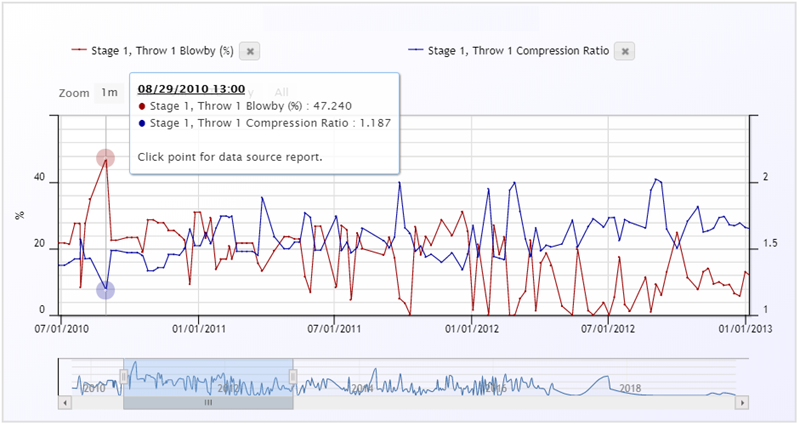

Definitively identifying improper valve springing from an individual Enalysis report is difficult, but a trend of Blowby vs compression ratio will show an inverse relationship between these two variables over time. Valve performance reduces with reductions in compression ratio, as indicated by spikes in Blowby, such as the one identified in the trend below. Inversely, increases in compression ratio cause the Blowby to drop, indicating an increase in valve performance. In the trend below, Blowby is red and the compression ratio is blue.

When valves are resulting in high blowby at low compression ratios, working with your valve supplier to optimize the valves for the conditions can result in improved valve performance, leading to a drop in power consumption, an increase in capacity, and/or a drop in suction pressure.

Excessive Lube Rates

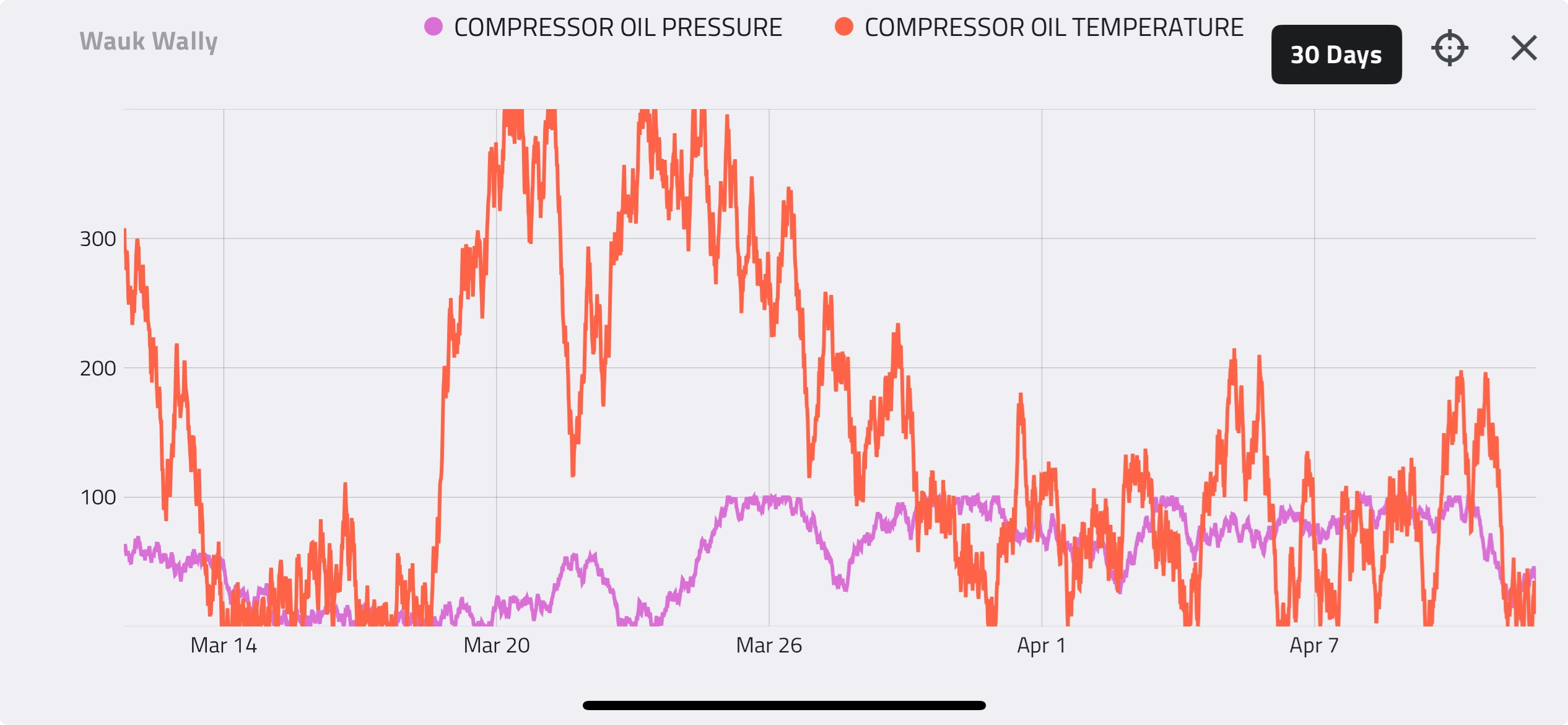

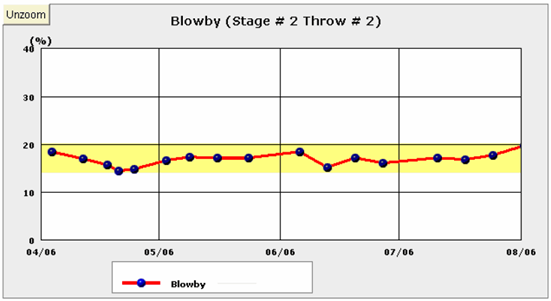

If the Blowby trend shows consistent high levels of Blowby, it is possible that the cylinder lubrication rates are too high. This is most common in newer compressors or compressor that have recent undergone a major overhaul. Most manufacturers recommend a break-in period with increased lubrication rates. Break-in rates can be 150% to 200% higher than normal rates and are often recommended for the first 200 hours of operation. The higher lube rate helps cool components and flush away any debris from the assembly/overhaul. If the lube rates are not adjusted after the first service, the oil consumption will be high, which is costly, but it can also contribute to excess power consumption.

When lubrication rates are excessive, the valves become coated in an oil film. The combination of adhesive forces between the oil and the valve seat and the oil and the valve plate and the cohesive forces within the oil causes stiction that resists the valve plate moving away from the valve seat. Breaking this stiction each time the valve opens and closes requires additional energy and results in excess heat.

Excessive lubrication usually presents as relatively constant high blowby and, most often, on multiple cylinders. This is because it is uncommon to have a force feed lubrication system feeding a single cylinder. It is likely that the system feeds one side or all cylinders of the compressor.

If your compressor exhibits Blowby trends that suggest your machine may have high lubrication rates, work with your Detechtion Technologies EAM or the compressor manufacturer to determine the correct lubrication rates for your compressor.

As a quick check, Ariel Corp has published the “Cylinder Lubrication Paper Test” as a viable field inspection method:

Cylinder Lubrication Paper Test

- This test estimates the amount of oil present on the cylinder bore by transferring oil from the bore to thin layers of unwaxed cigarette paper.

- The paper test should be performed within one hour of stopping the unit to get the best representation of cylinder oil film during operation. The test is carried out by the following steps:

- Using light pressure, wipe the cylinder bore with two layers of regular unwaxed cigarette paper together. Begin at the top and wipe downward about 20° (between 1/4” to 4-5/8” depending on bore size) along the bore circumference. The paper against the bore surface should be stained (wetted with oil), but the second paper should not be soaked through.

- Repeat the test at both sides of the bore at about 90° from the top, using two clean papers for each side. Paper against the bore surface not stained through may indicate under-lubrication; both papers stained through may indicate over-lubrication.

(“Lube Reduction in Reciprocating Compressors.” Ariel Corp, https://www.arielcorp.com/Technical-Papers/Lube-Reduction-in-Reciprocating-Compressors/. Accessed 29 April 2020)

Click hear to read Enalysis Tip 1.7 - Gauge Maintenance Result for Gas Compressor on Enalysis Report now!