2 min read

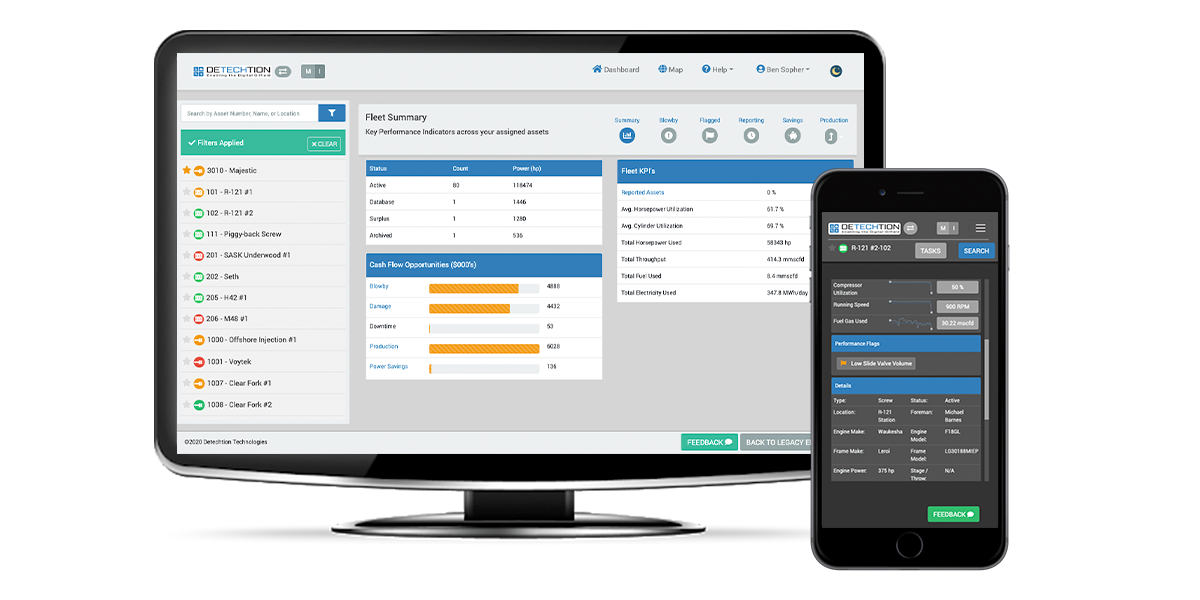

Enalysis Version 5.0 - Delivering Value Through Remarkable Usability

Detechtion Technologies, the proven Asset Performance Management, Industrial IoT, and Mobile Field Services Management solution provider in the...

2 min read

Detechtion Technologies, the proven Asset Performance Management, Industrial IoT, and Mobile Field Services Management solution provider in the...

4 min read

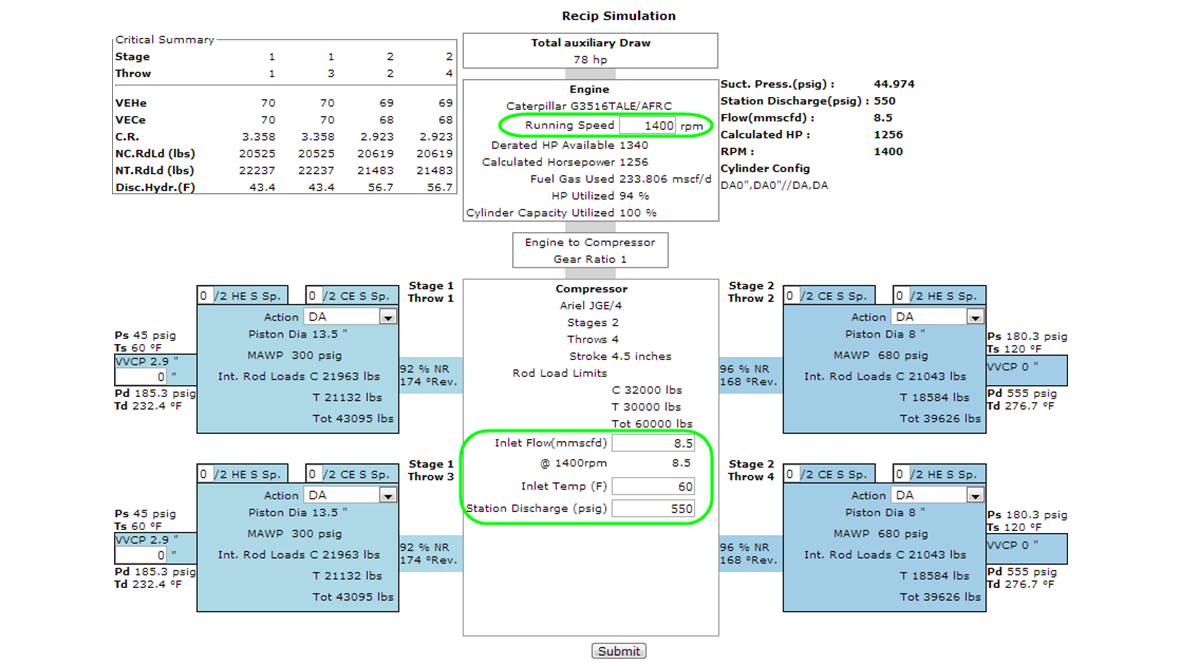

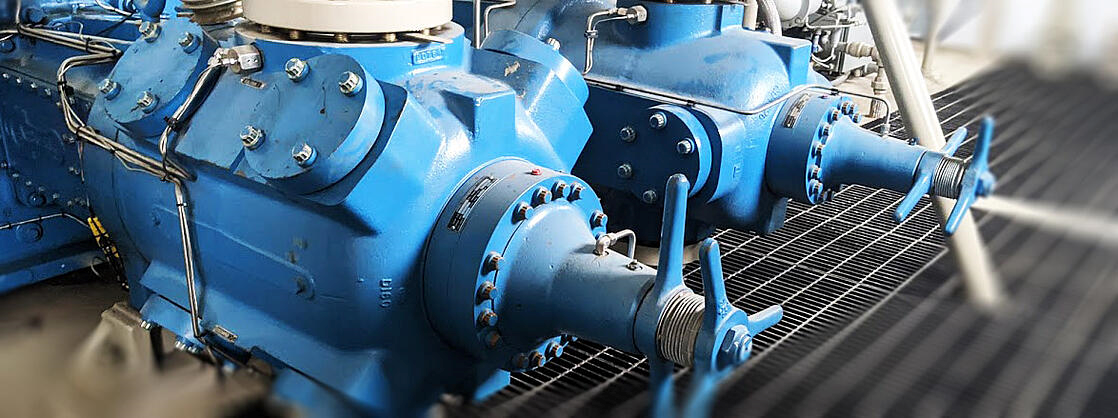

Enalysis includes a full-featured compressor simulator for all active units enrolled in the software. The simulator uses the same calculations and...

3 min read

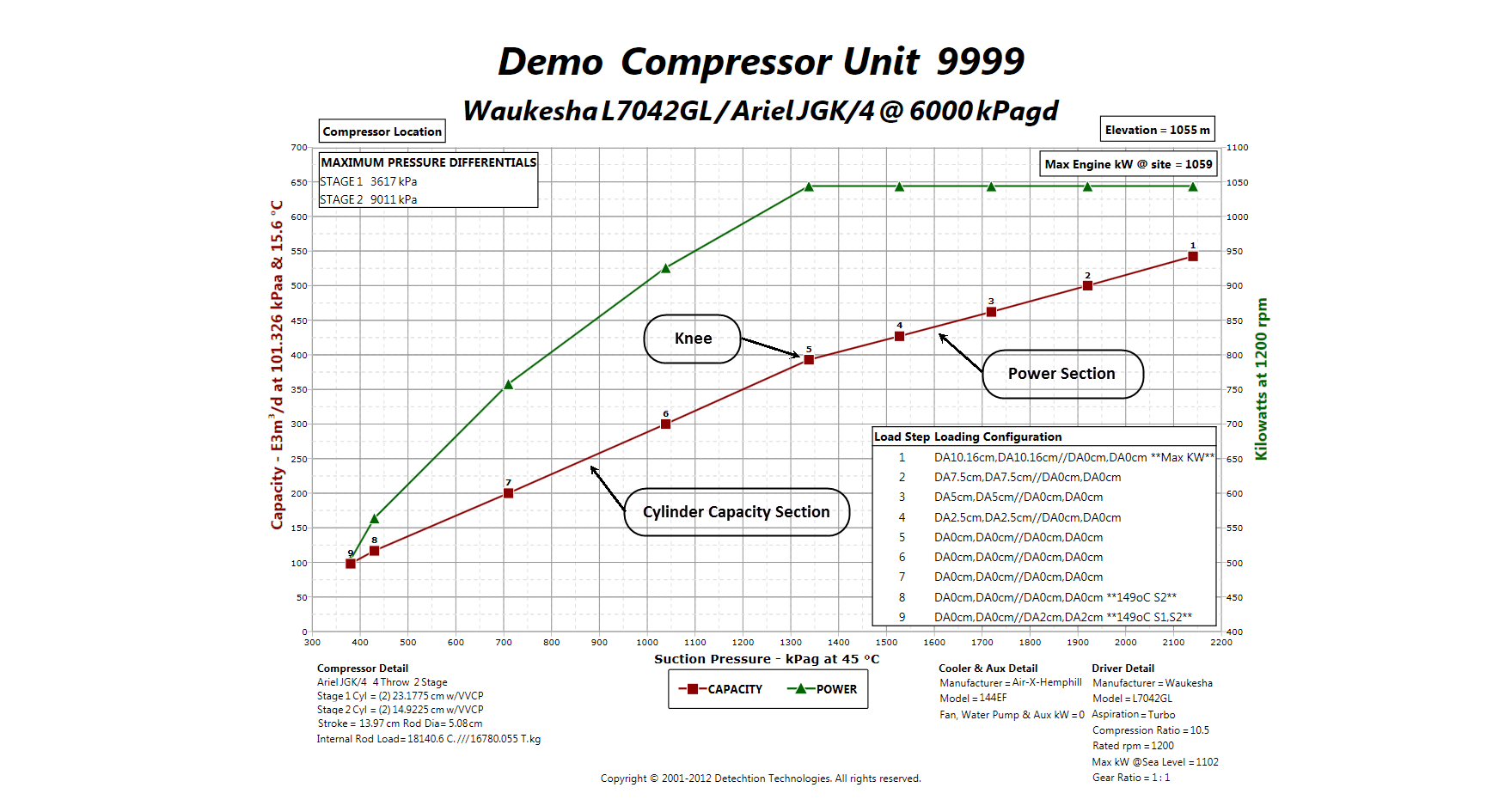

In natural gas gathering applications, maintaining the lowest possible suction pressure can provide a significant production advantage. As fields...

2 min read

At Detechtion, one of the the things we obsess over is optimizing fleets of natural gas compression equipment by reducing operating costs and...

3 min read

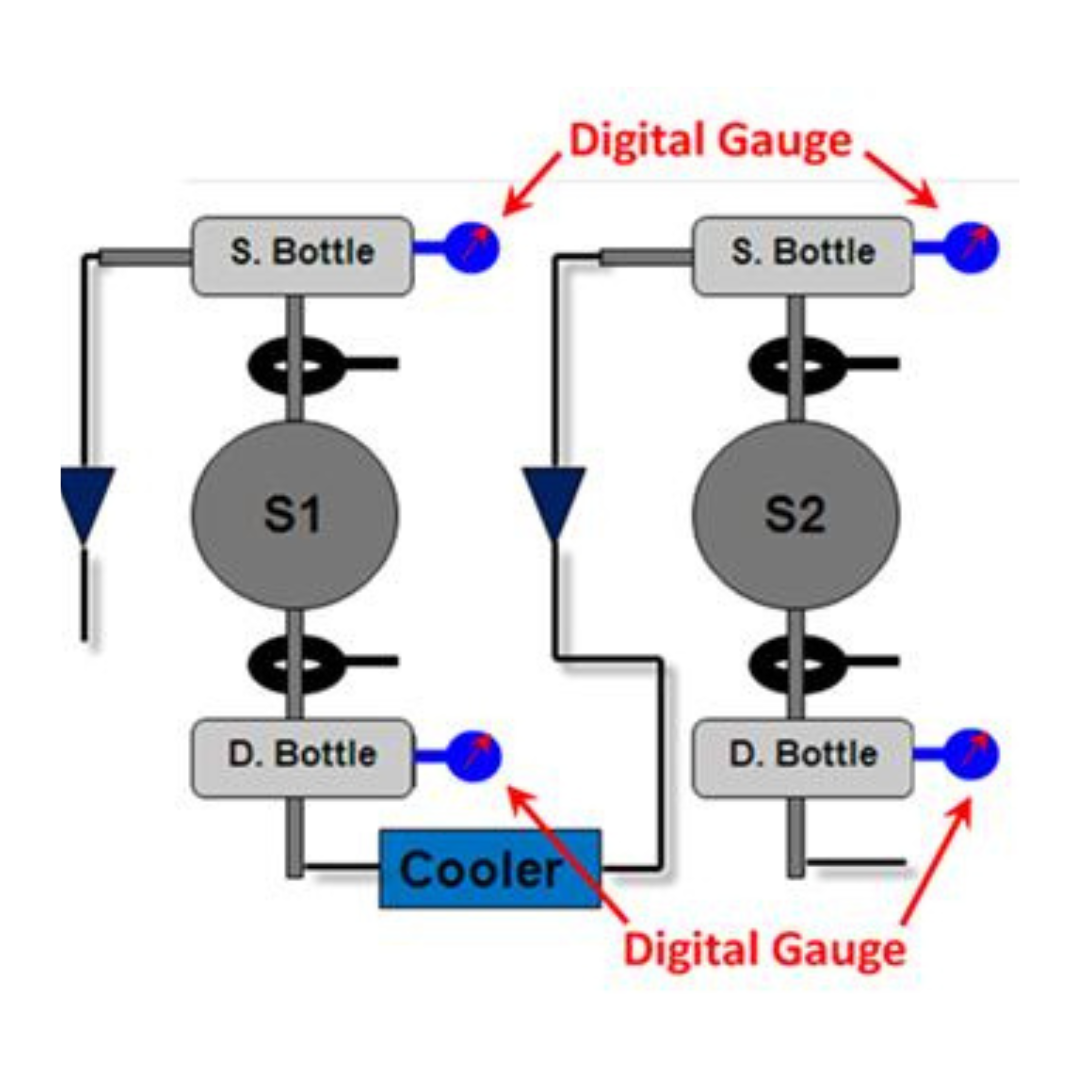

This post will look at how unaccounted pressure drops effect the Blowby calculated in an Enalysis report from Detechtion Technologies. Enalysis...

2 min read

Enalysis is a web-based predictive SaaS (Software as a Service) program combining geometric software models of compressors and thermodynamic...

1 min read

Welcome to E-Tips, a new initiative to assist you to get the most out of Enalysis®. Enalysis is a powerful and unique, web-enabled software tool for...