4 min read

Enalysis Tip 1.10 - Reciprocating Compressor Limitations

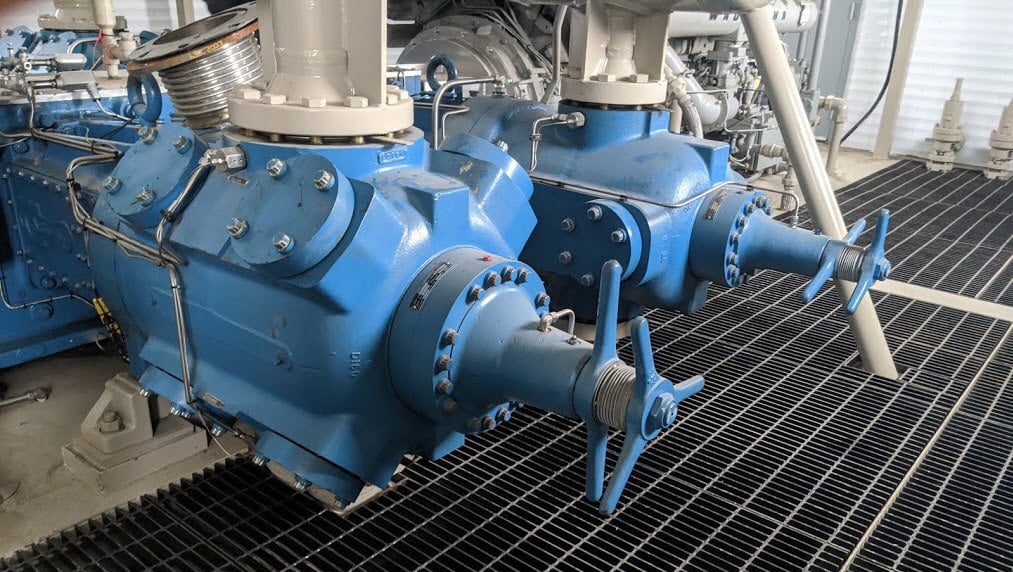

Reciprocating compressor packages are restricted to operating under conditions that ensure the mechanical ratings of the compressor are not exceeded....

4 min read

Reciprocating compressor packages are restricted to operating under conditions that ensure the mechanical ratings of the compressor are not exceeded....

4 min read

Did you know that all Enalysis users can use Fieldlink to enter compressor field data into Enalysis? Fieldlink eliminates the need for any paper data...

2 min read

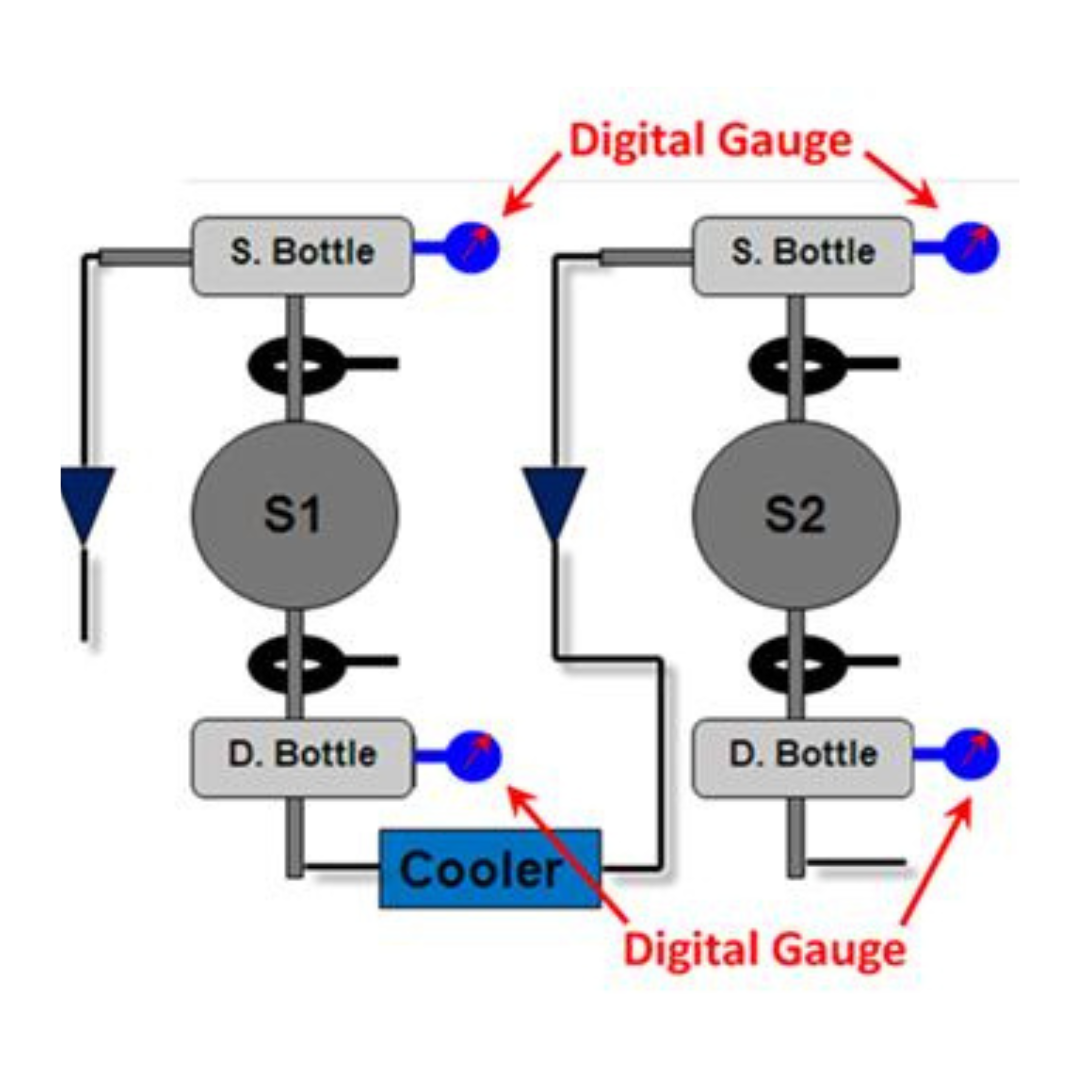

This post will provide Detechtion Technologies’ recommended steps for troubleshooting Blowby and “Gauge Maintenance”. These two concepts, along with...

4 min read

“Gauge Maintenance” is the term used by Detechtion Technologies when the monitored compressor parameters are thermodynamically impossible according...

3 min read

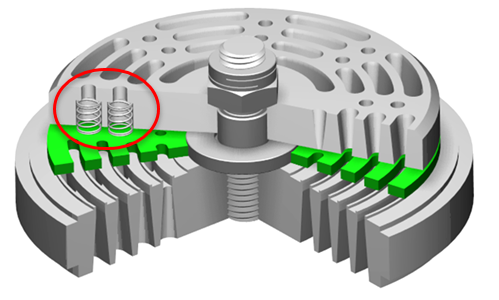

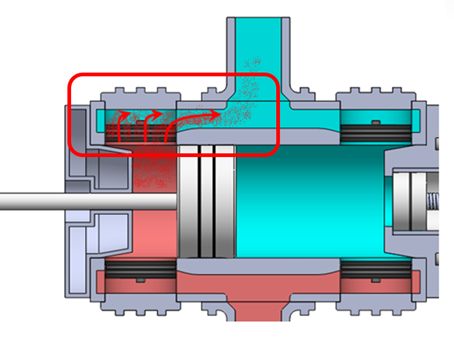

Blowby can result without any physical damage to wear components or unaccounted pressure drops. Improper valve springing can lead to valve flutter,...

3 min read

This post will look at how unaccounted pressure drops effect the Blowby calculated in an Enalysis report from Detechtion Technologies. Enalysis...

3 min read

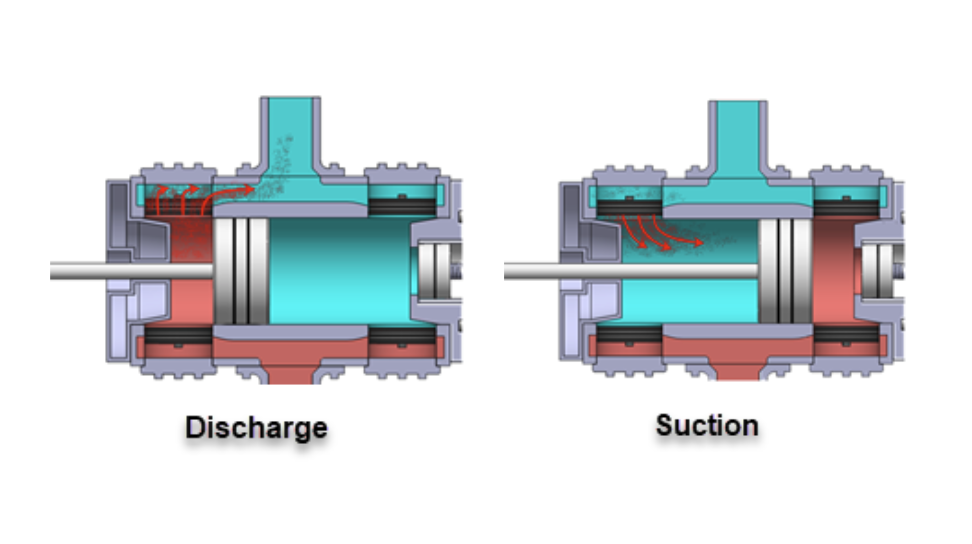

As mentioned in the last E-Tip, “Blowby” is a term used by Detechtion Technologies to quantify inefficiencies in the compression process. Blowby is...

3 min read

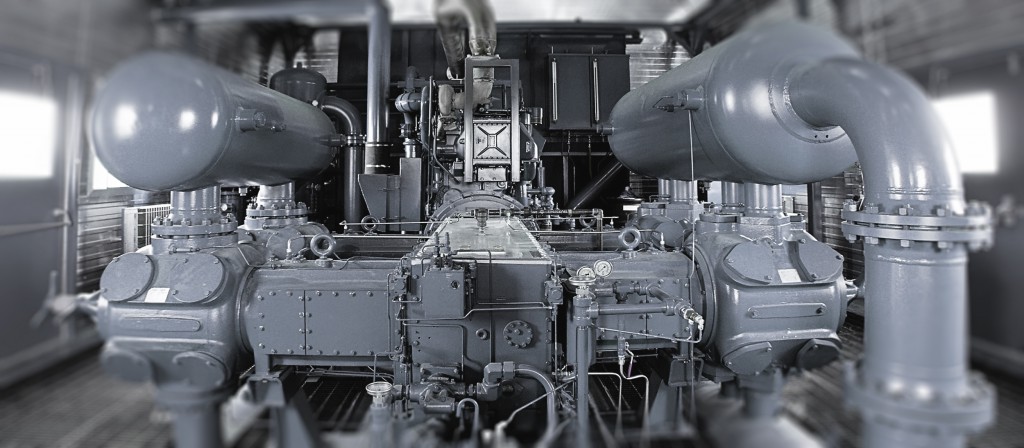

More than two thirds of the unplanned downtime of reciprocating compressors can be attributed to issues with the wearing components in a cylinder....