3 min read

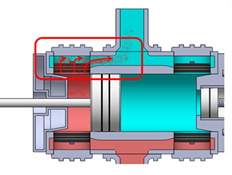

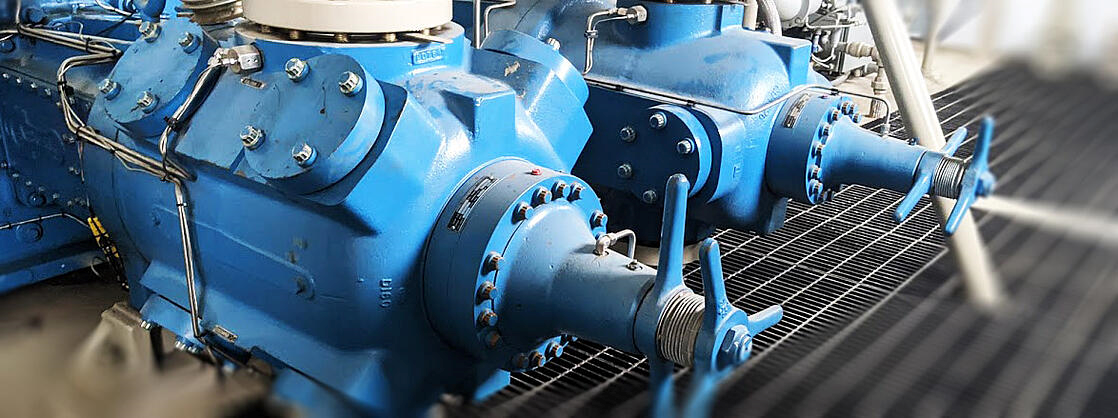

Enalysis Tip 1.3 - Detechtion Blowby and Cylinder Health

More than two thirds of the unplanned downtime of reciprocating compressors can be attributed to issues with the wearing components in a cylinder....

3 min read

More than two thirds of the unplanned downtime of reciprocating compressors can be attributed to issues with the wearing components in a cylinder....

2 min read

Enalysis is a web-based predictive SaaS (Software as a Service) program combining geometric software models of compressors and thermodynamic...