Learn more about how you can benefit from the latest version of Enalysis and contact us today!

Houston, TX |

Enalysis offers a new and greatly improved user experience allowing customers to better identify, investigate and act on valuable opportunities for improving their assets and fleetwide performance. In addition to improving the overall user experience, Enalysis delivers new features in a rapidly evolving market, and the capability for users to work seamlessly on their mobile devices.

The focus for this post is to walk through how a user can identify, investigate, and evaluate power saving opportunities utilizing the latest version.

Background on Power Saving Opportunities

Detechtion committed itself to helping its clients further reduce operating costs by introducing algorithms aimed to identify cost saving opportunities. The calculation set provides an accurate approximation of the power savings achievable for the inefficiencies identified by Enalysis, which is then translated into an annual operating cost reduction.

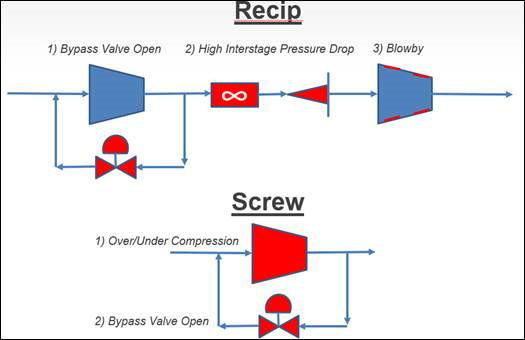

Inefficiencies are identified in assets based on:

- the amount they are bypassing/recycling.

- the pressure drops between stages.

- any inefficiency within a cylinder or excessive over/under compression in rotary screw compressors.

The most impactful power saving opportunities are instances where the compressor is recycling gas when it is unnecessary. In other words, the asset is compressing more gas than is required, leading to inefficiencies.

To improve performance of the asset in the scenario where the asset is bypassing gas, the compressor often must undergo a configuration change to decrease utilization (eg. Reduce RPM, Open Pockets, Install Spacers, Single-Act, Reduction to set-points, etc). In our experience, unless you can associate a tangible benefit to reduction to utilization, the perceived benefit to move these projects and opportunities forward is low.

Optimizing for power savings can be a low capital, high return project. Enalysis is the tool that is used to both identify the fuel/power saving opportunity, and to determine the best optimized configuration to achieve that goal.

Identifying Power Saving Opportunities

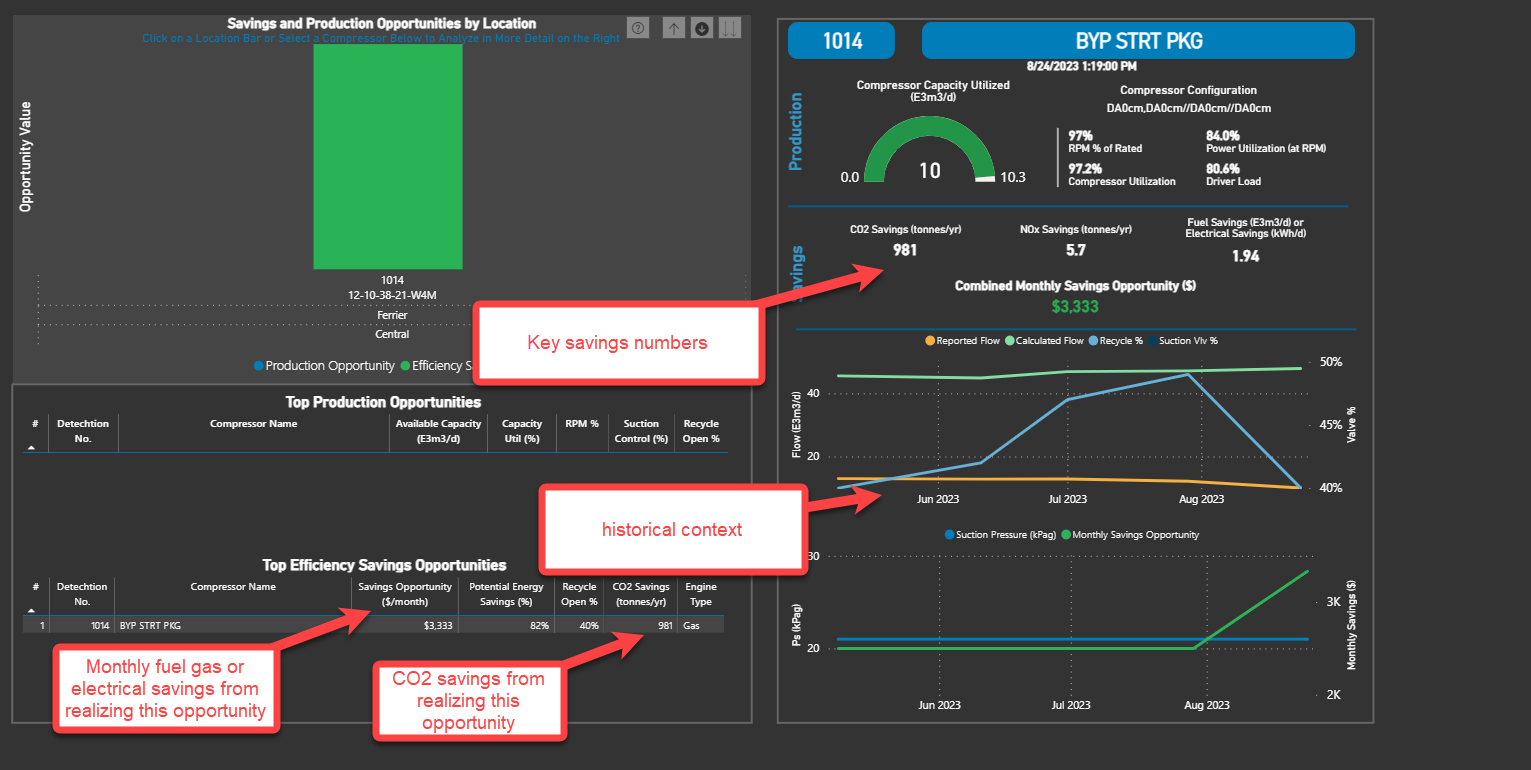

With Enalysis Insights you can easily see where your power savings opportunities are, anywhere in your fleet. The green bars represent the magnitude of the power savings opportunity and can be drilled down to identify specific areas, fields and units that have the largest opportunity.

Investigating Power Saving Opportunities

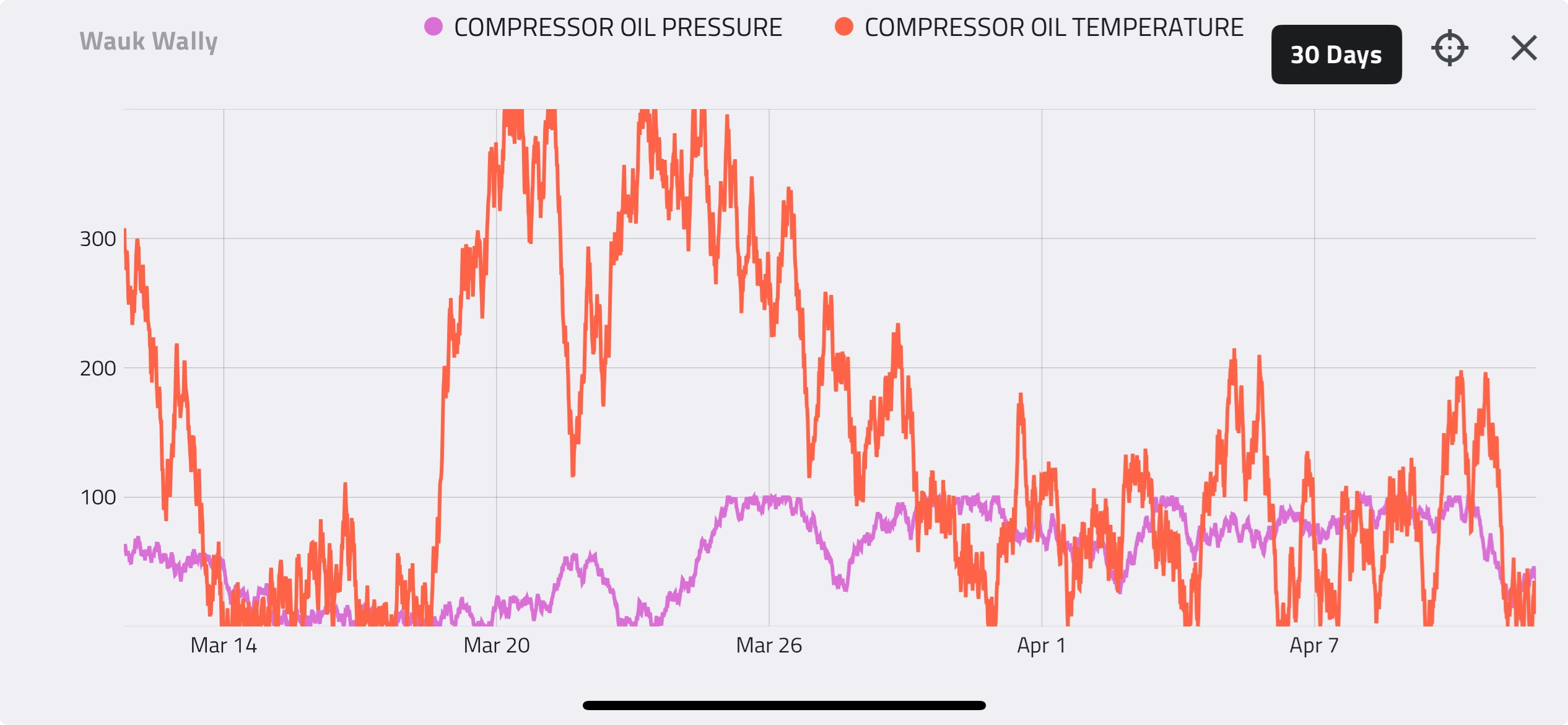

When you've identified an asset that presents an opportunity for optimization, utilize the vital signs to assess the performance and operating conditions of your asset. To better evaluate your equipment performance, it is best to understand its expected and desired operating range.

The following example highlights the types of details we would want to capture before moving on to the evaluation step.

| Parameter | Value (Current) | Value (Target) |

| Suction Pressure (psig) | 3 | 3 |

| Discharge Pressure (psig) | 260 | 260 |

| Production (mmscfd) | 0.35 | 0.35 |

| Capacity (mmscfd) | 1.6 | Lower! |

| Fuel Usage (mscfd) | 67 | Lower! |

Based on this data, the goal will be to maintain the current pressures and production with reduced fuel usage.

The following image of Enalysis Insights highlights how to find yielded carbon savings when the power savings opportunity is utilized.

Evaluating Power Saving Opportunities

Once the optimization goal is determined, use the Enalysis Simulator to determine whether the previously it can be achieved.

To perform the simulation, a user can navigate directly from vital signs to the simulator.

For performing the simulations, please refer to the following post for details:

Performance Modeling with Enalysis Simulator

The outcome of the simulation exercise indicates that production and pressures can be maintained while reducing total fuel usage from 67mscfd to 24mscfd by reducing the assets total capacity. The capacity reduction is achieved by reducing the speed to the drivers minimum speed of 1200, and further capacity reduction by opening pockets and non-acting one of the first stage cylinders.

| Parameter | Value (Current) | Value (Target) | Change | Comment |

| Suction Pressure (psig) | 3 | 3 | - | |

| Discharge Pressure (psig) | 260 | 260 | - | |

| Production (mmscfd) | 0.35 | 0.35 | - | |

| Running Speed | 1800 | 1200 | Require Speed Reduction | |

| Configuration | DA0",DA0"// DA0"//DA0" |

NA,DA2"// DA0"//DA1" |

Require further Capacity reducion by opening pockets and Non-Acting | |

| Capacity (mmscfd) | 1.6 | 0.53 | -1.07 | Capacity still exceeds production |

| Fuel Usage (mscfd) | 67 | 25 | -42 | Reduced Fuel Usage |

| Annual Fuel Cost (@$2.00/mscfd) | $ 48,910.00 | $ 18,250.00 | -$ 30,660.00 | Reduced Fuel Cost |

If the new configuration is deemed promising, utilize the "send to engineer" functionality to receive a more in-depth review of the asset’s limitations, and guidance on how to set the compressors operating set points.

The following video outlines how you can utilize the Enalysis simulator in combination with the operating data from the asset’s vital signs to evaluate the validity of the opportunity.