Digitally Transforming Your Compression Monitoring System:

6 ways you can can streamline operations, reduce risk, and increase revenue

Why Manage Your Natural Gas Compression System by Exception?

More and more oil and gas producers and midstream companies are trying to move towards management by exception within their operations. And their natural gas compression programs are no exception. Whether managing a fleet of operator owned units, leasing units from one or more contract compression service providers, or likely a heterogenous fleet with a combination of both, the first step in the journey to management by exception is setting up a monitoring infrastructure to provide transparency needed to make this pivot.

Without a remote monitoring infrastructure in place, you are truly driving blind! While you might have any level of local monitoring and automation in place using various compression annunciators and controllers, engine control systems and PLCs, you cannot run a proactive and predictive maintenance program without visibility to that data. In this disconnected world, operators typically struggle with:

- Calendar- based preventative maintenance (PMs) that do not take into account the actual usage and operating condition of the equipment.

- Unplanned callouts triggered by unscheduled shutdowns, or "news" of a shutdown that may or may not occurred.

- No insight or information on the unplanned callout. Was it a production issue? Or something mechanical? unclear when to send someone or who to send.

- Little or no visibility to accurate downtime and your true asset availability.

With a remote monitoring program in place, however, it is like shining a big, bright spotlight on your operations giving you visibility to data you never had before. Integrated data from sensors on the compressor provides transparency to accurate availability and other key operating information. You can pivot your preventative maintenance program from being calendar-based to a more efficient usage or run hours-based program, often allowing you to perform less frequent PMs.

You also get greater clarity when to send someone to the site with alarm notifications upon shutdown. And you get some insight into why the compressor went down, allowing you to send the right person with the right tools for the job. Callout acknowledgment allows you to ensure that the right person responds to the job and escalates to the appropriate supervisors or management when the job is not responded to or completed in a timely fashion.

This all reduces unnecessary trips to the site and importantly minimizes your mean time to repair and compressor downtime.

The Importance of Mobile Oilfield Management Solutions for Managing Field Workers and Workflows

But what about the operating data that is not instrumented? While a remote monitoring program is critical to bringing data from sensors on your equipment, there is often other key data that has to be collected by field workers. These field technicians and mechanics are shooting valve caps and collecting other vital data while onsite that is essential to completing the picture.

These same field workers are also performing critical tasks on the equipment including responding to unplanned callouts, performing PMs, or undertaking other maintenance activities like compressor overhauls. Whether it’s your employees performing this work or third-party service providers, confirming that the job was performed, parts consumed, and other data about the job is equally important to understanding equipment.

Many producers have implemented Computerized Maintenance Management Systems (CMMS) or more comprehensive Enterprise Asset Management (EAM) software to track their assets and the associated maintenance and reliability programs. But these systems often sit behind your IT firewall and are not extended out into the oilfield. It is not uncommon for employees to receive and track their activities on paper only to key it into the system later in the day on their laptops when they are back in the field office or even back home. This leads to significant data latency and quality issues and presents a huge barrier to running an efficient compression management program – particularly one that is aiming for management by exception.

Thankfully, these challenges can be overcome with Mobile Oilfield Management solutions. Mobile Oilfield Management software can replace paper-based work processes that are still all too common today with modern, digital data collection and workflows.

- Support a “bring your own device” running on any phone, tablet or laptop

- Work offline so workers can still get their job done even at remote locations

- Have a simple, familiar interface so field workers enjoy a single UI for all their field work – not multiple different apps with different logins and different terminology

- Available to all field workers including both employees and their service providers

- Integrate with and extend your back-office systems including your EAM software into the oilfield

These mobile solutions enable the accurate and timely collection of data from your equipment that is not instrumented with sensors today. They additionally enable the accurate and timely collection of all associated field work including callouts, performing PMs, and other maintenance activities with auditable date, timestamp, GPS coordinates, signatures and photos of work performed.

Seeing is Believing.

Learn how Detechtion's solutions can help you control. monitor, and optimize your assets.

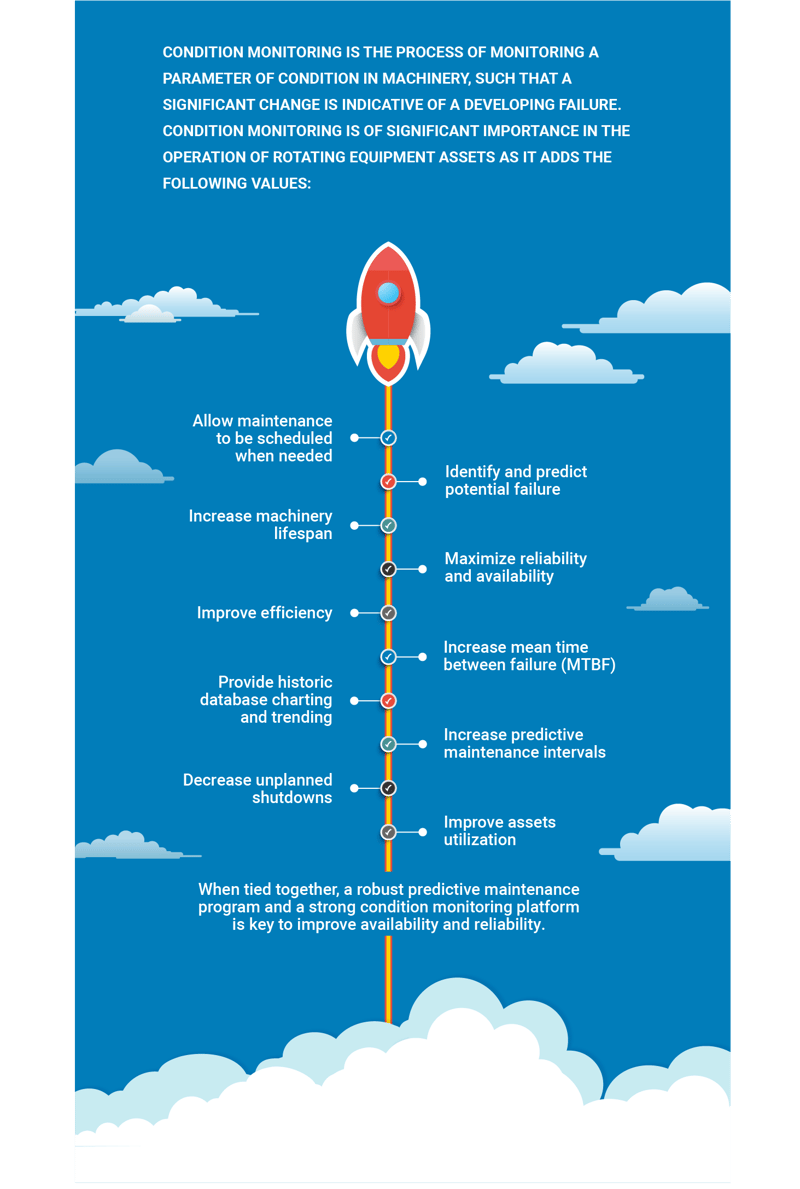

Predictive Maintenance and Condition Monitoring with Natural Gas IIoT

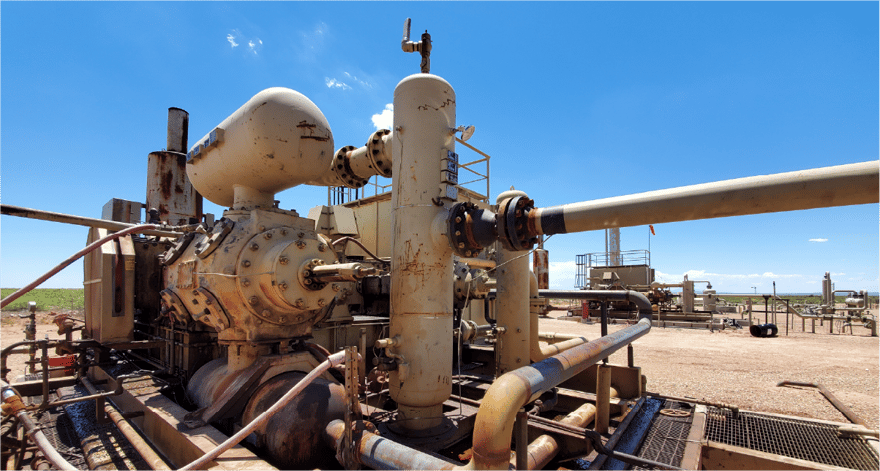

The oil and gas industry faces many challenges, including the need to improve efficiencies and to increase reliability to achieve operational excellence. Those challenges are too often accentuated by the remoteness of production assets and/or by a fragmented maintenance strategy.

When integrated with a remote monitoring program or a Mobile Oilfield Management solution, an Asset Performance Management (APM) platform can be used to clearly visualize and analyze operating data to surface developing failures and operational opportunities.

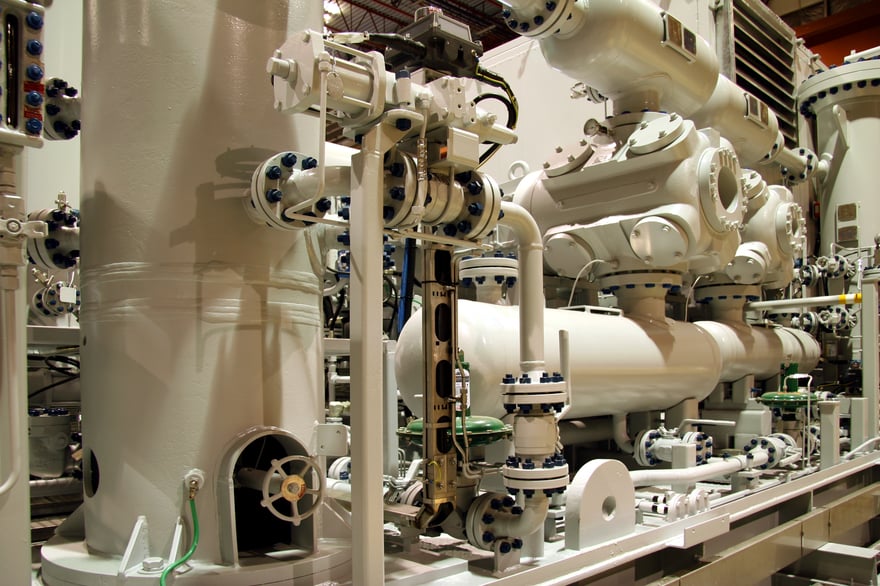

As part of a maintenance strategy, an APM platform allows industry experts to assess and monitor the condition of production assets. More precisely an APM is used to visualize and analyze operating conditions like temperatures, pressures, and vibrations to name a few. Then a robust analytic engine provides insights on the health of mechanical components and notify users when potential failures are developing, nearing safe equipment limits or achieved operational optimization.

How to Get the Most Out of Your Natural Gas Compression Assets

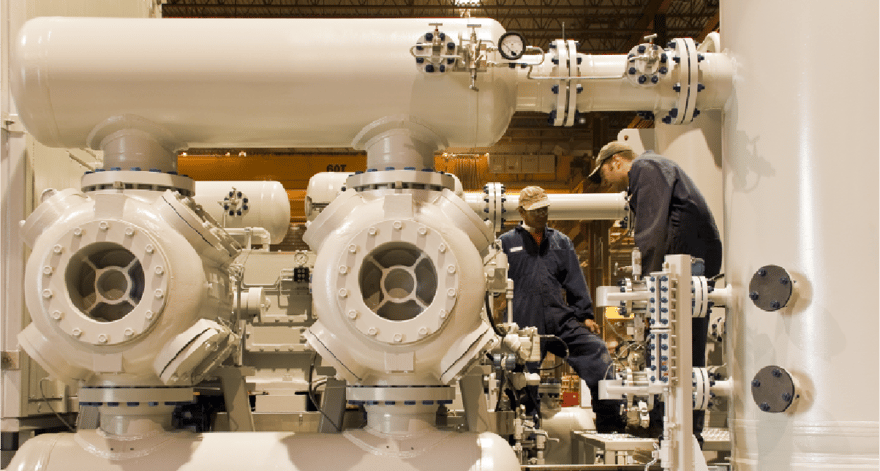

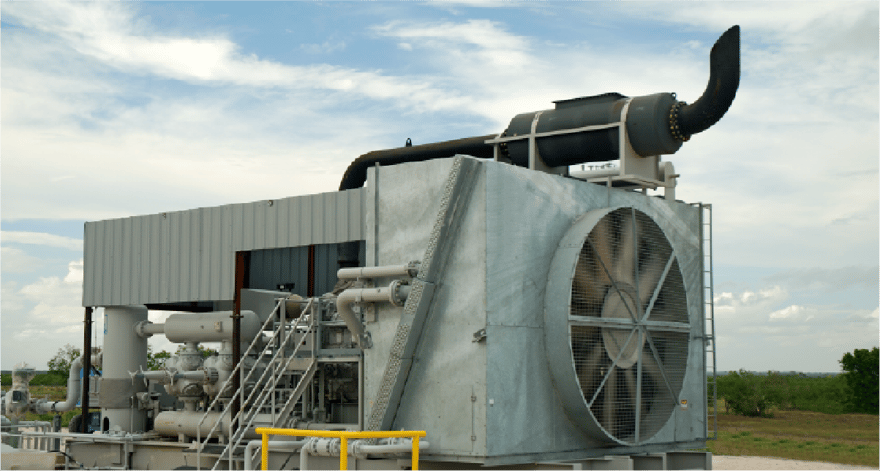

The compressor is the heartbeat of the natural gas pipeline system and is a key component of any natural gas production operation. One additional challenge oil and gas producers and midstream companies face is the optimization of their compression assets to achieve desired goals.

Optimizing a compressor can have different meanings based on operating goals and/or operating conditions. It can go from maximizing the throughput to increasing the reliability to lower power usage or to lower emissions.

In a competitive natural gas gathering application, maintaining the lowest suction pressure can provide a significant production advantage to any gas producer. To maximize the throughput of a compressor there are two concepts in play. First, the gas must go through the initial stage of a compressor before going through the rest of the asset which emphasizes the importance of maximizing the capacity of the first stage cylinder(s). Second, the capacity of a compressor increases as a result of increasing the suction pressure, meaning the suction pressure is dictated by the flow of the compressor or vice versa. In summary, the capacity of a positive displacement compressor increases as the suction pressure rises and the production of a natural gas well tends to increase as the suction pressure drops. Depending on the field response, the goal is to stimulate the well and to maximize the performance of the compressor. An APM platform can identify production opportunities for compression assets and guide industry experts to capitalize on production opportunities.

On the other hand, compression assets can be underutilized, which often results in excessive power consumption. This generally occurs when the potential capacity of a compressor is above the amount of gas the field can deliver. In this scenario, maximizing the power usage of a compression asset becomes a key element of reducing operating expenses. To optimize the power usage, the capacity of the compressor needs to be adjusted to the amount of gas the well can deliver.

Without a strong Asset Performance Management (APM) platform is difficult to oversee a fleet of compressors where operating goals and operating conditions may vary from field to field. One size does not fit all.

Closing the Loop with Mobile Oilfield Management Solutions

Once you identify predictive maintenance and compressor optimization opportunities, how do you dispatch the right technician or mechanic to the field to ensure that the job is completed? That is again, where Mobile Oilfield Management comes in. Whether you create these opportunities as work orders in your EAM/CMMS system or not, they can be sent to the field for action using Mobile Oilfield Management software. From there it is dispatched, and the job is completed, and a full history of the work performed and any parts consumed is captured – all with auditable date, timestamp, GPS coordinates, signatures and photos of work performed. We call this “closing the loop.”

Whether the job resulted in a replaced piston ring or valve preventing a more costly repair (and downtime), prevented catastrophic failure (due to excessive rod load or insufficient rod reversals), or reconfiguring the compressor to move more gas or operate more efficiently, the compressor is now running at an optimized state. New operating data is collected from sensors through remote monitoring or by field workers with Mobile Oilfield Management software. Algorithms run on the new data looking for the next opportunity, either on this compressor or elsewhere in the fleet. And the process of managing by exception continues.

How Detechtion’s Solutions Can Save You Money

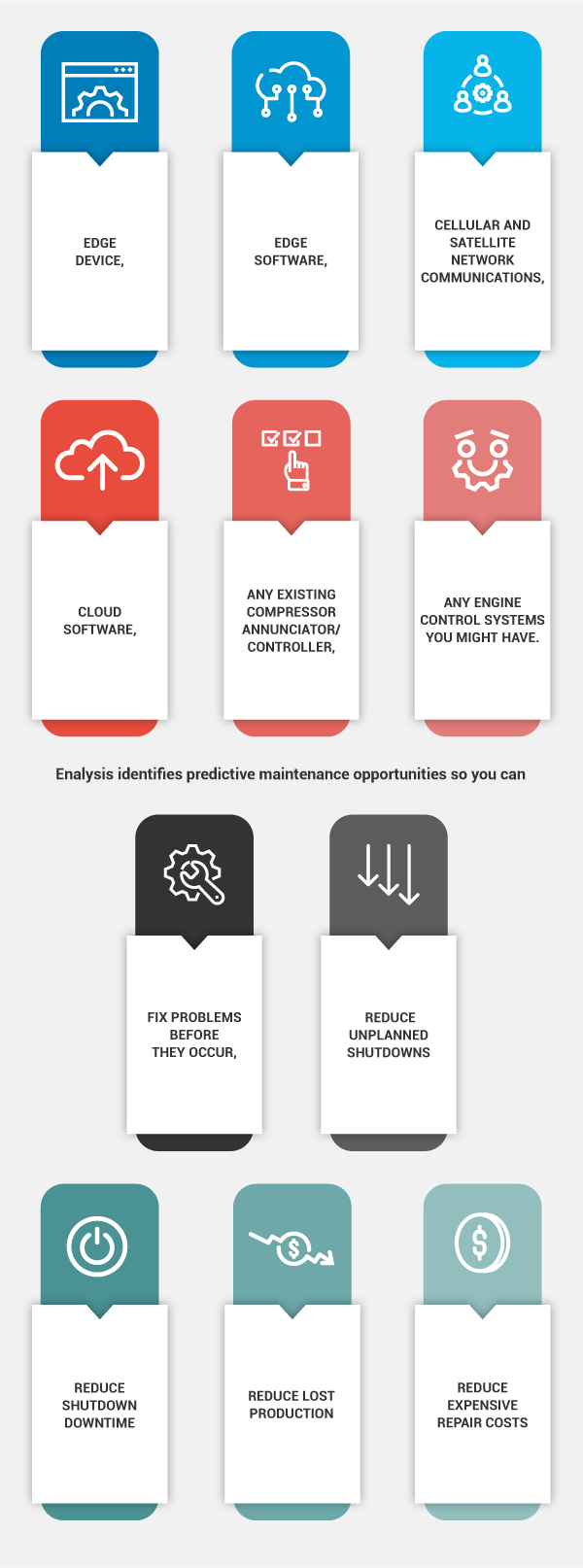

Producers use Enbase to remotely monitor their entire fleet of natural gas compressors. Enbase provides a complete turnkey, integrated solution for remotely monitoring both reciprocating and rotary screw compressors including

Operators can save additional costs by using this insight to further extend PM schedules when needed.

Enalysis also identifies production optimization opportunities to increase throughput or reduce fuel/power consumption – or sometimes both. These opportunities are additionally ranked for the producer with predictive maintenance opportunities based on our proprietary Cashflow at Risk KPI to ensure that the operator is sending field workers where they can make the biggest impact on the business.

Producers use Fieldlink to digitize and automate field workflows performed by mechanics or field service technicians ranging from

- JOB SAFETY/HAZARD ASSESSMENTS

- CALLOUTS

- PREVENTATIVE MAINTENANCE

- OVERHAULS

Or any other field activities.

Fieldlink is Mobile Oilfield Management software providing service companies like yours with a single app built for the oilfield that runs on any phone, tablet or laptop and works offline so workers can get their work done even on remote locations.

WITH ENBASE, ENALYSIS, AND FIELDLINK, DETECTHION CAN HELP YOU...

- Implement alarm notifications for all shutdowns including ability to require field technicians to acknowledge alarms and escalate if not acknowledged

- Ability to route alarms differently for mechanical versus production issues depending on who has “first call” obligation between you and your service provider(s)

- Perform less frequent PMs

- Reduce unnecessary trips to site

- Complete accurate runtime and availability data

- Maximize compressor shutdown setpoints

- Predictively identify maintenance issues before they occur, allowing you to address them before they lead to more costly repairs (and downtime)

- Predictively identify signs of catastrophic failure, allowing you to proactively shut down the unit and resolve the issue

- Configure your compressor to optimum performance – whether it’s moving more gas, reducing fuel gas/power consumption, or finding the most efficient configuration to run your compressor to meet your goals

- Provide full transparency and auditability of PM and callout work performed

- Allow for review and approval of all fieldwork, and integrate complete work with time/parts consumed into your accounting/financial as well as EAM/CMMS systems

- Provide critical data needed to properly manage fluids, expenses, inventory, emissions and warranties

Monitor, Control and Optimize.

Schedule a demonstration with our experts and see how we can help your fleet gain visibility and control.