Houston, TX |

Natural Gas Compression Basics 3 in this series covered the compression cycle for a reciprocating compressor. In addition to explaining the compression process, it introduced the concept of unswept clearance volume in the cylinder and its effect on the compression cycle and cylinder capacity. This E-Tip will further explore compressor capacity and the total gas throughput, or flow, of the compressor.

Piston Displacement

Piston displacement is a function of the physical dimensions of the cylinder, the compressor stroke length and the running speed, RPM. The displacement is equal to the net piston area multiplied by the length of piston sweep in a given period of time.

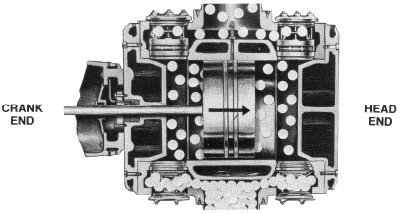

In the case of the double-acting cylinder, the displacement of both the head end and the crank end of the cylinder must be considered. While the net piston area of the head end is simply a function of the piston diameter, the piston rod must be considered when calculating the net piston area of the crank end. The crank end displacement is less than the head end displacement by the amount the piston rod displaces.

In the case of the double-acting cylinder, the displacement of both the head end and the crank end of the cylinder must be considered. While the net piston area of the head end is simply a function of the piston diameter, the piston rod must be considered when calculating the net piston area of the crank end. The crank end displacement is less than the head end displacement by the amount the piston rod displaces.

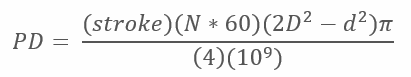

For a double- acting piston (other than tail rod type), piston displacement can be calculated as:

Where:

- PD = piston displacement (m3/h)

- N = speed (rpm)

- Stroke = Compressor stroke length (mm)

- D = cylinder inside diameter (mm)

- d = piston rod diameters (mm)

For multi-stage units, the combined piston displacement of all the first stage cylinders is often used to describe the displacement of the compressor. While the performance of the higher level stages influence the capacity, the gas must enter the first stage before it can be compressed on to the higher level stages and, eventually, the discharge pipeline.

Compressor Capacity

A compressor’s gas capacity depends on how many molecules of gas will fit into the first stage displacement volume, which is influenced by the suction pressure and temperature, as covered in Compression Basics 1 – Gas Properties, but also how much of the displacement is useable. Not all the displacement can be filled with gas that will eventually be discharged from the cylinder. This ratio of capacity to displacement is called the Volumetric Efficiency and is influenced by the clearance volume of the cylinder (VVCP, pockets, spacers, etc), the compression ratio and gas specific heat ratio.

Compressor capacity is defined as the actual volume rate of flow (ACFM) or gas compressed and delivered at conditions of total temperature, total pressure, and composition prevailing at the compressor inlet.

This capacity is converted to standard conditions of 101.325kPaa (absolute) and 15 °C (14.696 PSIA and 60oF) and is measured in thousands of cubic meters per day, e3m3/d (millions of cubic feet per day, MMSCFD).

This capacity is converted to standard conditions of 101.325kPaa (absolute) and 15 °C (14.696 PSIA and 60oF) and is measured in thousands of cubic meters per day, e3m3/d (millions of cubic feet per day, MMSCFD).

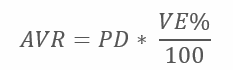

Capacity is defined as the displacement multiplied by the volumetric efficiency. Therefore:

Where:

- AVR = actual volumetric rate (m3/h)

- PD = piston displacement (m3/h)

- VE% = volumetric efficiency (%)

Volumetric Efficiency

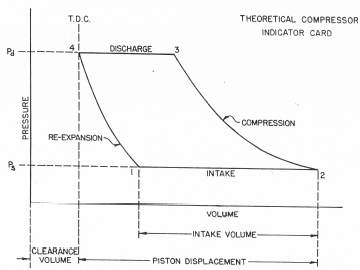

In a reciprocating compressor the piston does not travel completely to the end of the cylinder at the end of a discharge stroke. Some clearance volume is necessary, and it includes the spaces between the end of the piston and the cylinder head when the piston is at the end of its stroke. It also includes the volume in the valve ports, the volume in the suction valve guards and the volume around the discharge valve seats.

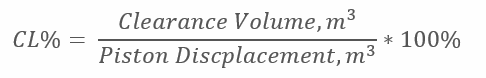

Clearance volume is usually expressed as a percent of piston displacement and is referred to as percent clearance, or cylinder clearance, CL%.

Beyond the minimum required base clearance, additional clearance can also be added to the cylinder.

Volumetric efficiency is the ratio of the capacity of the compressor to the displacement of the compressor. Since a compressor will not deliver an amount of gas equal to its displacement, the volumetric efficiency will always be less than one.

The volumetric efficiency is varied by the clearance in the cylinder, the compression ratio, any slippage or blow-by of the gas being compressed, and finally by the characteristics of the gas being compressed.

For double-acting cylinders, the percent clearance is based on the total clearance volume for both the head end and the crank end of the cylinder. These two clearance volumes are not the same due to the presence of the piston rod in the crank end of the cylinder. Sometimes additional clearance volume is intentionally added to reduce the cylinder capacity. This is most commonly achieved by adjustments to the variable volume clearance pockets, VVCPs, or the installation of valve spacers or cylinder clearance plugs.

The term “volumetric efficiency” refers to the actual pumping capacity of a cylinder compared to the piston displacement. The effect of the gas contained in the clearance volume on the pumping capacity of a cylinder can be represented by:

Where:

- 96 = account for suction and discharge valve losses

- CR = compression ratio

- CL% = clearance percentage

- Zs = suction compressibility

- Zd = discharge compressibility

- k = specific heat ratio at suction conditions

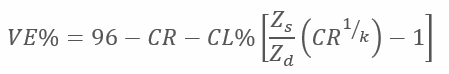

Effect of Added Clearance

The percentage of clearance will affect the capacity of the compressor and the horsepower required. It is sometimes necessary to add more clearance to meet the design conditions. From the volumetric efficiency equation above, increasing clearance will reduce volumetric efficiencies and reduce cylinder capacity. Therefore, clearance is most commonly added to:

- Reduce capacity at fixed suction pressure conditions.

- To prevent driver power overload by reducing compressor capacity to reduce compression ratio through elevated suction pressures.

The image below shows how increasing clearance reduces volumetric efficiency and compressor capacity.

(Bloch & Hoefner, 1933)

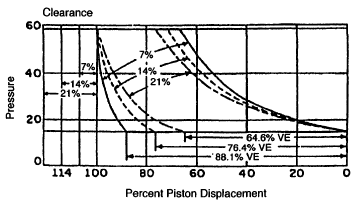

Effect of Compression Ratio

The image below shows how an increase in compression ratio will reduce the volumetric efficiency. As the compression ratio increases, a greater change in volume is required to allow the gas trapped in the clearance volume to expand back to suction pressure, thus less of the stroke is available to bring new gas into the cylinder.

(Bloch & Hoefner, 1933)

Maximising Compressor Throughput

The capacity of a reciprocating compressor is maximised when the clearance and the compression ratio is at a minimum and the compressor is operated at full rated speed. To achieve this, there should be no added clearance and the compression ratio of the first stage should be reduced as much as possible. The latter should be achieved by optimising downstream equipment and processes and optimising higher levels of compression in multi-stage compressors. Of course, all of this must be achieved within the physical limits of the compressor and the power limits of the driver.

The following relationships were stated in the introduction to this Compression Basics E-Tip series:

Capacity (Q) is function of

Displacement (D) and Volumetric Efficiency (VE%)

Volumetric Efficiency (VE%) is a function of

Clearance (CL%) and Compression Ratio (CR)

Power (KW/HP) is a function of

Capacity (Q) and Compression Ratio (CR)

The first two have been covered in detail in this E-Tip. In the next E-Tip in this series, we will explore how capacity, compression ratio and operating pressures effect the power required for compression.