Unified Fleet Visibility for Compression Operations.

Teams managing a fleet of compressors lose time and trust when compressor data is scattered, stuck in data silos, and split across vendor portals with multiple logins. Add inconsistent data, telemetry issues, and mismatched downtime logic, and you end up with no single source of truth.

OneView Compression™ platform gives you a single, unified dashboard for compressor monitoring across your fleet with consistent, trustworthy compression data, no matter where it comes from. That way, you can spot issues faster, validate downtime with confidence, and improve service relationships through stronger vendor accountability and clearer vendor performance tracking.

All Your Compressors.

One View. One Truth.

OneView Compression™ platform connects to existing telemetry systems to standardize compressor data across all assets. It unifies runtime, measurements, downtime, and alarm data into one fleetwide view so you can act sooner.

Unlike general BI tools, OneView includes compressor-ready data structures and standardized downtime logic, so your team doesn’t have to build and maintain the model.

No duplicate logins. No additional hardware rollouts. Less manual reporting. Just clean, actionable visibility for better day-to-day decisions.

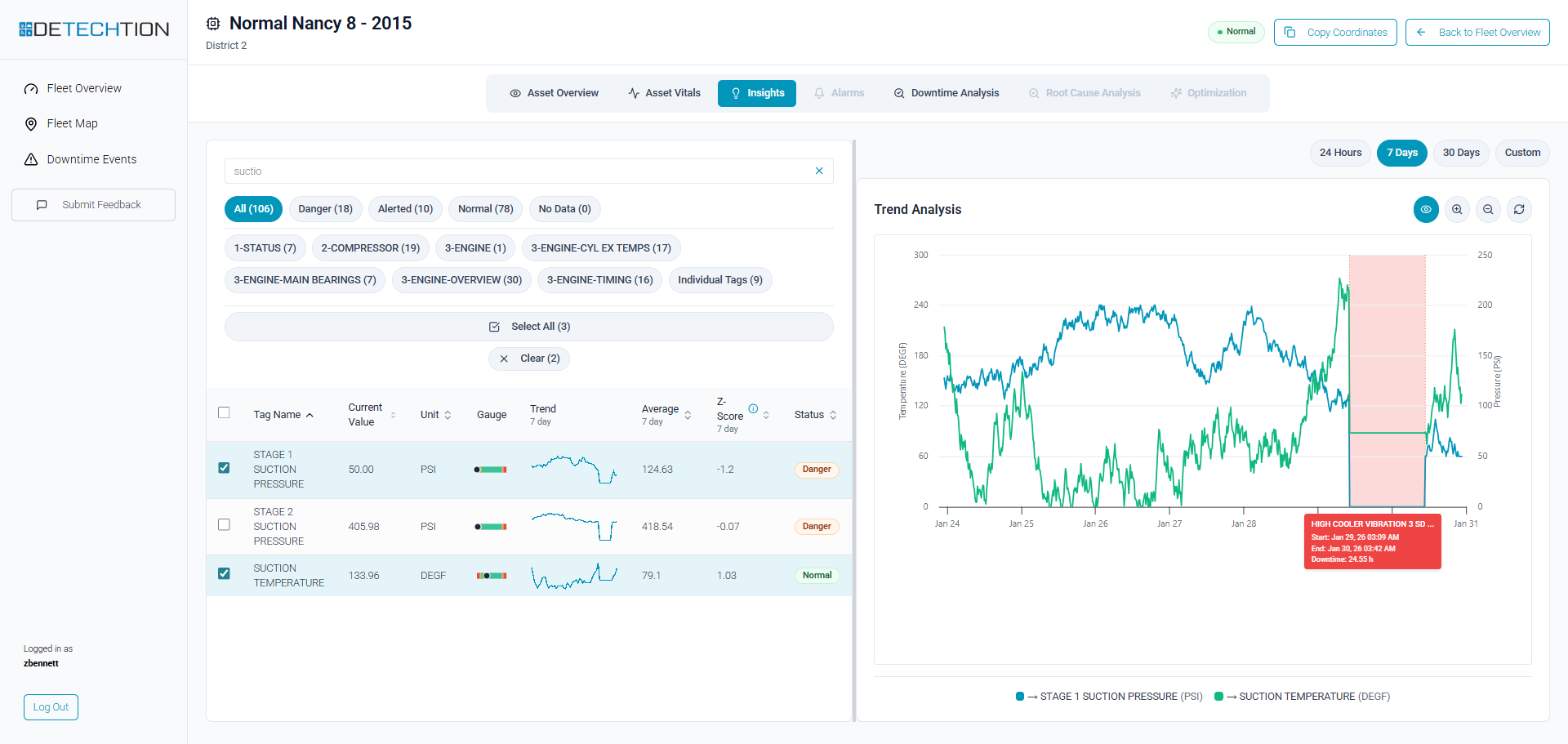

Decision-Ready Visibility

Get a unified fleetwide view of your compressors with data you can trust, regardless of vendor or telemetry system. Reduce time lost to data scattered across portals, data gaps, and inconsistent data.

See your entire compressor fleet in a single, unified view across all vendors, sites, and telemetry systems.

.png?width=297&height=277&name=Improved%20Data%20(1).png)

Integrate data from existing telemetry hardware and multiple vendors without requiring new installations.

.png?width=231&height=232&name=Operations%20Managers%20(1).png)

Work with measurement, runtime, and downtime data that is organized, consistent, and easy to interpret.

Built for Compressor Data, Not Generic Dashboards

OneView standardizes and curates compressor data across your fleet, creating a strong foundation for deeper insights.

Compressor-ready data structures + standardized downtime logic

So your team doesn’t have to build and maintain the model.

Catch Data Issues Before They Drive Downtime

When stale data, dark assets, and data gaps hide what is happening in the field, teams lose time and default to reactive decision-making. OneView helps surface telemetry health issues earlier so your team can respond with better context.

This supports better downtime validation, clearer handoffs, and fewer surprises during downtime tracking and reporting workflows.

Optional Advanced Analytics Layer

When this unified data flows through advanced analytics, such as a digital twin powered by our industry-leading Enalysis software, you can unlock:

- Optimization opportunities

- Early failure risk indicators

- Fleet and asset performance KPIs

This optional layer builds on your operational foundation, helping teams move from reactive maintenance toward a more proactive approach. It can also support a roadmap toward predictive maintenance through Enalysis.

OneView Technical Snapshot

|

Architecture:

|

Cloud-native, API-first platform built for secure, scalable data ingestion.

|

|

Compatibility:

|

Works with any system that exposes compressor measurement and alarm data with no proprietary hardware required.

|

|

Vendor Neutrality:

|

Compatible with leased and owned fleets, across multiple telemetry vendors.

|

|

Security:

|

Role-based access control within a cloud-native, secure architecture.

|

|

Scalability:

|

Proven from 10 units to enterprise-scale deployments (1,500+ assets).

|

|

Data Foundation:

|

Normalized runtime, alarm, and downtime tables structured for advanced analytics and optimization.

|

|

Data Frequency:

|

Supports ~15-minute data refresh intervals (depending on source system).

|

|

Deployment Model:

|

Fully managed SaaS with no on-premise infrastructure.

|

Teams That Use OneView

Managing owned or leased compressors from multiple vendors

Needing consistent runtime/downtime data for analysis

Focused on uptime, performance, and accountability

Wanting transparent and standardized data to strengthen service relationships

What You Gain with OneView

Current |

With OneView |

|---|---|

|

Fragmented data across vendors and telemetry platforms

|

All compressor data unified in a single, trusted dashboard

|

|

Manual downtime verification and reporting

|

Automated, normalized downtime tracking and root-cause analysis

|

|

Limited insight into vendor performance

|

Transparent accountability backed by standardized data

|

|

Reactive maintenance response

|

Data foundation for predictive maintenance through Enalysis

|

FAQ

Do we need to install new hardware to use OneView?

Usually not. OneView is software-first and connects to existing telemetry and data sources through APIs and available exports. If a site has no telemetry at all, we will review options during discovery.

Which telemetry systems and vendor platforms can OneView connect to?

OneView works with systems that expose compressor measurement and alarm data. We can confirm compatibility quickly by reviewing your current sources and what they can provide.

How does OneView standardize downtime logic across different vendors?

OneView normalizes downtime across the fleet using consistent logic and clear source attribution. This makes it easier to validate downtime and compare performance across vendors and sites.

How long does it take to get OneView up and running?

Timing depends on the number of source systems and the mapping required. Many teams start with a focused pilot, then expand in phases across the fleet.

How often does OneView refresh data?

OneView can support approximately 15-minute refresh intervals, depending on the cadence and availability of the source system. Refresh timing is driven by what your telemetry or platform can provide.

What is included in the optional advanced analytics layer, and how does it relate to Enalysis?

OneView provides the unified fleet view and standardized data foundation. With the optional analytics layer, OneView data can power Enalysis digital twin analytics for deeper performance and reliability insights.

We already use Power BI or another BI tool. Why do we need OneView?

Most BI tools still require your team to build and maintain the compressor data model and downtime standards. OneView includes compressor-ready data structures and standardized downtime logic, so you get a trusted fleet view faster with less ongoing maintenance.

Explore our other Technologies

Unlock Your Fleet’s Potential.

Unify, Optimize, and Empower Your Oilfield Operations

Unlock $150K in hidden value per compressor.

Ready to Unify Your Compressor Data?

Request a demo to see how OneView Compression™ can unify your compressor data, accelerate decision-making, and establish the foundation for predictive optimization

Ready to Unify Your Compressor Data?

Request a demo to see how OneView Compression™ can unify your compressor data, accelerate decision-making, and establish the foundation for predictive optimization

Longfellow Energy Upgrades to the Detechtion Compressor Control Panel

Learn how one client integrated a modern panel that would consolidate all monitoring and control systems into one seamless platform.

Compression 101

An introductory guide to the basics of natural gas, compression, types of compressors and the capacity and power behind natural gas compressors.