Houston, TX |

At Detechtion we like to talk a lot about how using our products together delivers more complete workflows to yield better business results. Whether you’re closing the loop on compressor optimization recommendations from Enalysis by dispatching field personnel with EZ Ops or implementing a complete chemical management program with EZ Ops(for batch treatments) and Enbase (for continuous treatments), Detechtion can help you digitally transform and optimize your oilfield operations.

But today we live in very turbulent times dealing with the global impacts of COVID-19 and a rapidly deteriorating price of oil. What our customers urgently need today is very simple: COST SAVINGS! And Detechtion can help deliver some very immediate cost savings to your business. One of the most fundamental building blocks of the Detechtion product portfolio is remotely monitoring your oilfield assets using Enbase products.

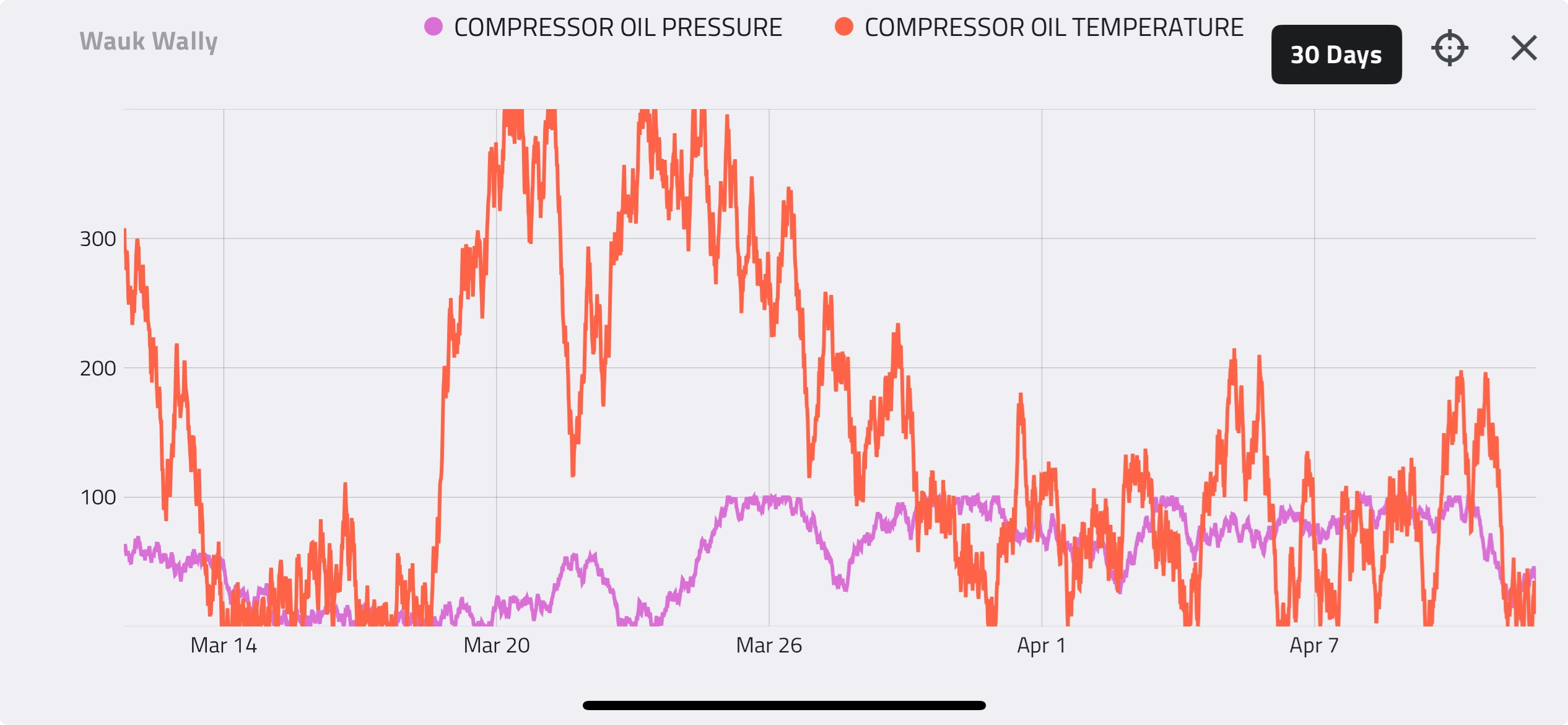

The Enbase Hub, our flagship edge device, can remotely monitor your oilfield asset giving you visibility to its current running conditions, including alarms when it shuts down with insights to why it shut down, from anywhere in the world – including on your laptop at home! One of the most basic benefits of this transparency is saving trips to site. You can operate by exception and only go to site when needed. And when a trip is required, you are armed with more complete information and insight ensuring that you’re sending the right person with the right tools and parts for the job.

The Enbase Tank Level Sensor can also be used to monitor your continuous chemical tanks. It will keep you updated with the current tank level, the number of days until the tank will be empty, and chemical injection rates (including alerting you to no-flow situations like when the pump is vapor locked).

Based on numbers provided by our customers, a typical compressor monitoring installation easily has a payback period of 5-6 months and a 12-month ROI of greater than 100%. One customer reported being able to achieve double the output with the same number of staff they required before using remote monitoring. Chemical tank monitoring can often achieve payback even quicker (just think: no more weekly inventory trips).

As you’re thinking about how you can do more with less in your own business, focus on any oilfield assets you have that are not currently remotely monitored and consider how Detechtion can help you meet your cost savings goals.