Houston, TX |

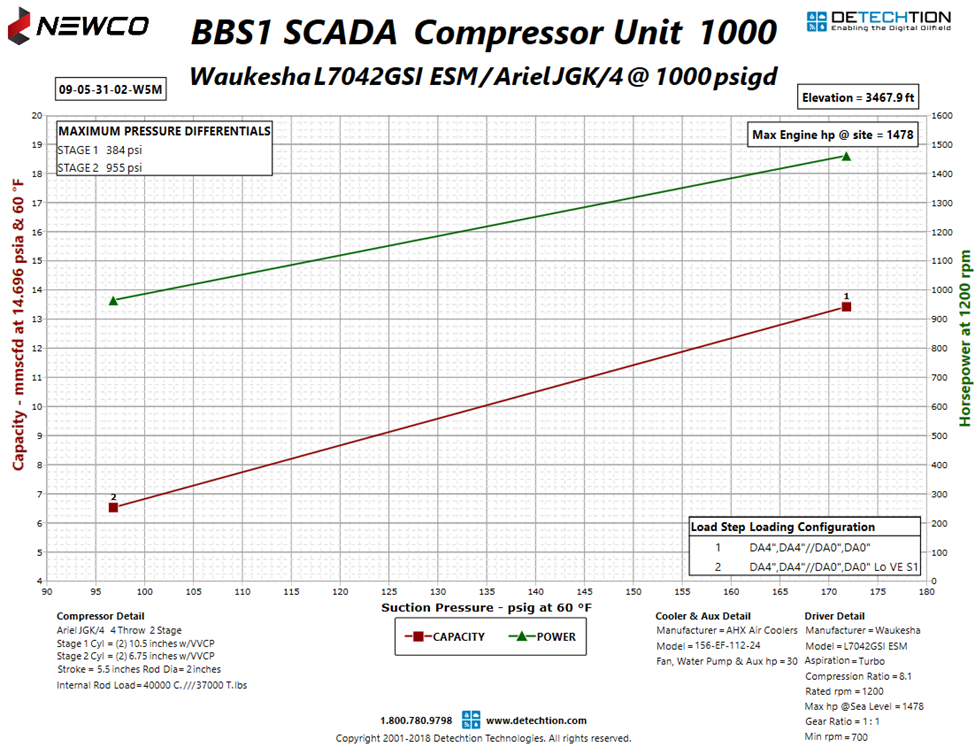

A gas gathering system can be confusing when you consider all the different competing variables and goals. In this post, let’s look at a common question you might have when first looking at a compressor curve. On the Min Max curve below (provided in combination with a Startup Package for a specific running configuration), we can easily see that as the suction pressure (horizontal axis) increases, the maximum achievable flow rate (vertical axis) increases. For a compressor running at a constant configuration (cylinder configuration, pocket positions and running speeds constant) as flow rate is increased, the suction pressure increases:

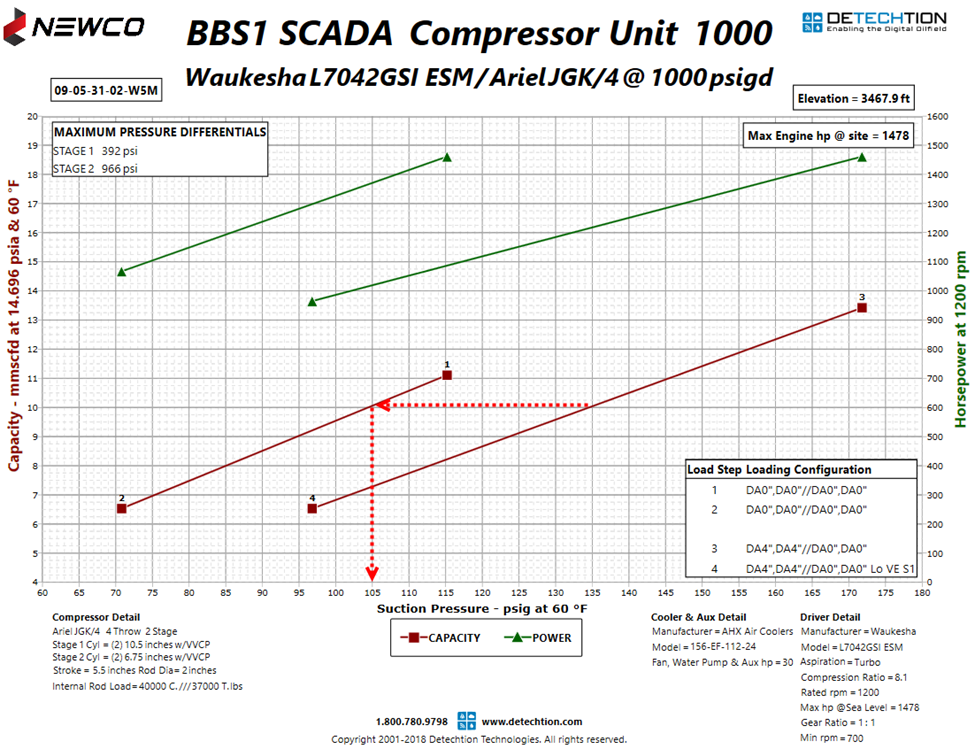

This is pretty straight forward until you get a call from your Engineering Account Manager telling you that there’s an opportunity to pull down the field. Based on the Enalysis report that they just received, they’re seeing that you’re moving 10mmscfd at a suction pressure of 135psig but there’s an opportunity to potentially move the same amount of gas while reducing the pressure by 30psig. This is confusing because if more pressure equals more gas, then the opposite would be true where less pressure equals less gas. This is 100% true, however the Engineering Account Manager isn’t talking about reducing the pressure by reducing the gas flowing to your site, they’re actually looking at your configuration and can see that if you were to close your first stage pockets from 4” to the 0” (fully closed), you can move the 10mmscfd at 105psig. This can be shown in the curve below:

The benefit of “pulling harder on the field” is that this could potentially reduce the upstream pressure which could make a difference all the way at your well-head, and when you consult your IPR (Inflow Performance Relationship) curves and evaluate the deliverability of your well or gathering system, you may find that the gathering system will deliver some incremental production. Even if your compressor has booster compressors in the field, lowering your gas plant pressures reduces the discharge pressures of those boosters, reducing HP utilization, and potentially allowing them to "pull harder" on the field.

If your compressor isn't fully loaded, and your production engineers can confirm that lower pressures would benefit the wells in your gathering system, please reach out. The Engineers at Detechtion would love to learn more about your site-specific goals, and provide not only the recommended pocket settings, but also the tailored shutdown setpoints (low suction, high discharge, bypass/suction control setpoints, max differentials, etc...) to ensure that you are in the best position possible to reap the full rewards of the configuration change.