2 min read

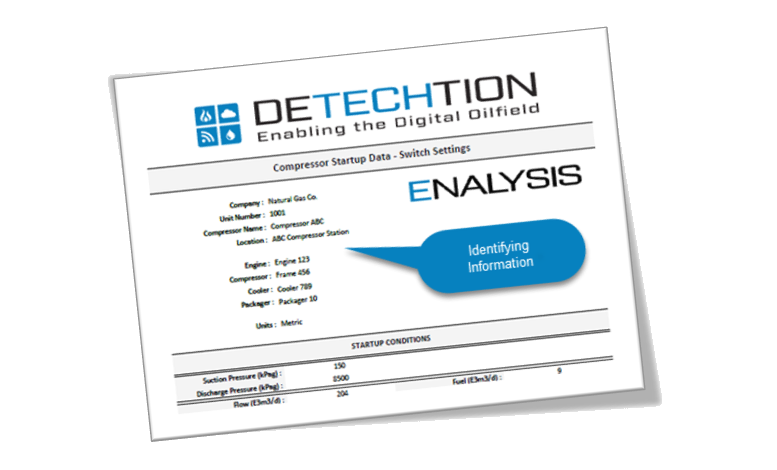

As Production Volumes Plummet, Users Depend on Detechtion to Deliver Cost Savings with Enalysis

At Detechtion, one of the the things we obsess over is optimizing fleets of natural gas compression equipment by reducing operating costs and...